MSDS (Material Safety Data Sheet), that is, the Safety Data Sheet of

Chemicals, can also be translated as Safety Data Sheets for Chemicals or Safety

Data Sheets for Chemicals. In European countries, MSDS is also known as SDS,

which is a document used by chemical manufacturers and importers to explain the

physical and chemical properties of chemicals (such as PH value, flash point,

flammability, reactivity, etc.) and possible harm to the health of users (such

as carcinogenicity, teratogenicity, etc.), containing a total of 16 contents.

1.Chemical

Product and Company Identification: It mainly indicates the name of the

chemical, the name of the manufacturer, the address, zip code, telephone

number, emergency telephone, fax and email address.

2.Information

on Hazardous Ingredients: Indicates whether the chemical is pure or a mixture,

including all hazardous substances containing more than 1% and carcinogens

exceeding 0.1%. If it is a pure chemical, the chemical name or trade name and

generic name should be given; In the case of mixtures, the concentration or

concentration range of the hazardous components should be given. Whether it is

a pure chemical or a mixture, if it contains a hazardous component, the

Chemical Abstracts Index Registry Number (CAS number) should be given.

3.Hazard

identification: Summarize the most important hazards of the chemical and its

impact on health, mainly covering hazard categories, invasion routes, health

hazards, environmental hazards, fire and explosion hazards and other

information.

4.First Aid

Measures: Self-help or mutual rescue methods (e.g., inhalation, ingestion, eye

contact, skin-to-skin treatment) in the event of an accidental injury.

5.Fire

Fighting Measures: It mainly displays the physical and chemical special hazards

of chemicals, suitable fire extinguishing media, unsuitable fire extinguishing

media, and personal protection of firefighters, including hazard

characteristics, fire extinguishing media and methods, fire extinguishing

precautions, etc.

6.意外泄露处置措施(Accidental

Release Measures):清理小型和大型泄漏的程序以及化学物质泄漏周围的具体规定。

7.Handling and

Storage: Provides information on the safe storage and safe use of materials.

8.Exposure

Control/Personal Protection: Protective methods and means used to protect

workers from chemical hazards in the process of producing, handling, handling

and using chemicals, including gloves, clothing, eye protection, and

respiratory protection.

9.Physical and

Chemical Properties: It mainly describes the appearance and physical and

chemical properties of chemicals, including appearance and properties, pH

value, boiling point, melting point, relative density (water = 1), relative

vapor density (air = 1), saturation vapor pressure, heat of combustion,

critical temperature, critical pressure, octanol/water partition coefficient,

flash point, ignition temperature, explosion limit, solubility, main uses and

some other special physical and chemical properties.

10.Stability

and Reactivity: Indicates stable substances, causes of instability and

incompatibility, including stability, prohibited substances, conditions under

which contact should be avoided, polymerization hazards, and decomposition

products.

11.Toxicology

Information: Provides toxicological information of chemicals, including acute

toxicity (LD50, LD50), irritation, sensitization, subacute and chronic

toxicity, mutagenicity, teratogenicity, carcinogenicity, etc.

12.Ecological

Information: It mainly states the environmental and ecological effects,

behaviors and outcomes of chemicals, including biological effects (such as

LD50, LD50), biodegradability, bioaccumulation, environmental transport and

other harmful environmental impacts.

13.Disposal

Considerations: refers to the safe disposal methods of chemical-contaminated

packaging and chemicals with no use value, including disposal methods and

precautions.

14.Transportation

Information: Mainly domestic and international chemical packaging,

transportation requirements and transportation regulations classification and

numbering, including dangerous goods number, packaging category, packaging

mark, packaging method, UN number and transportation precautions.

5.Regulatory

Information: Mainly legal provisions and standards for chemical management, as

well as CITES related EPA and OSHA regulations.

16.Other

Information: It mainly provides other information that is important to

security, such as references, time of filling in the form, department of

filling in the form, data review unit, etc.

In general, MSDS is used to determine

whether the goods are suitable for sea transportation and what appropriate mode

of transportation is used to ensure transportation safety. When booking a

specific cargo for export, the carrier (shipping company) will require an MSDS,

and all personnel who come into contact with or may come into contact with the

cargo (including loading and unloading personnel, depot/warehouse personnel,

etc.) will need an MSDS. Operators must follow the guidelines and instructions

of MSDS for correct operation and disposal, especially in emergencies such as

package damage and leakage, it is difficult to understand the situation without

MSDS, which will delay rescue, and blind action will lead to serious

consequences.

The 16 contents of the MSDS issued by

authoritative institutions are very accurate, for example, the Shanghai

Institute of Chemical Industry can issue them. But now basically the

manufacturer compiles the MSDS by itself, and the accuracy is not high, so many

times it is necessary to refer to the identification certificate to judge

whether it is ordinary goods or dangerous goods. In the actual trade and

transportation of chemical products, the accuracy of MSDS is extremely

critical. It is very common for manufacturers to compile their own MSDS

inaccurately, which makes there are many hidden dangers when judging the nature

of the goods. Since an inaccurate MSDS may not accurately reflect the

characteristics of chemicals, it may lead to misjudgment as to whether the

goods are suitable for sea transportation and what mode of transportation to

use.

When booking cargo, if the carrier is

acting on an inaccurate MSDS, it may transport the cargo that should have been

handled in accordance with the requirements for the transport of dangerous

goods as general cargo, or vice versa. Not only can this be a violation of

transport regulations, but it also poses a significant risk to transport

safety. For example, if an accident occurs during transportation, an inaccurate

MSDS cannot provide accurate information to rescuers, such as when a chemical

is leaked, it is difficult for rescuers to take effective response measures if

it is not clear about its hazard category and suitable fire extinguishing

medium.

Inaccurate MSDS can also prevent operators

from operating correctly during handling, disposal, and storage. For example,

for some chemicals that require special storage conditions, if the MSDS does

not accurately state, it may lead to improper storage, which can lead to

chemical reactions and safety accidents. When it comes to exposure control and

personal protection, the wrong MSDS can lead workers to use inappropriate

protective gear that prevents them from effectively protecting themselves from

chemical hazards.

For the measure of judging whether ordinary

goods or dangerous goods are made by referring to the appraisal certificate,

although it can make up for the inaccuracy of the manufacturer's self-compiled

MSDS to a certain extent, there are also some limitations. On the one hand,

obtaining an appraisal certificate can require additional time and cost; On the

other hand, there may be differences in standards and testing methods between

different accreditation bodies, which may also lead to inconsistencies in judgment

results.

To sum up, MSDS plays an indispensable role

in the production, transportation, storage and emergency treatment of chemical

products, but the current situation of inaccurate MSDS compiled by

manufacturers has seriously affected its function, and measures need to be

taken to improve the accuracy of MSDS to ensure the safety and orderly conduct

of related activities in the chemical industry.

In the actual trade and transportation of

chemical products, the accuracy of the MSDS is crucial. It is not uncommon for

manufacturers to compile their own MSDS inaccurately, which makes there are

many hidden dangers when judging the nature of goods. Since an inaccurate MSDS

may not accurately reflect the characteristics of chemicals, it may lead to

misjudgment as to whether the goods are suitable for sea transportation and

what mode of transportation to use.

When booking cargo, if the carrier relies

on an inaccurate MSDS, it may transport the cargo as general cargo that should

have been handled in accordance with the requirements for the transport of

dangerous goods, or vice versa. Not only can this be a violation of transport

regulations, but it also poses a significant risk to transport safety. For

example, if an accident occurs during transportation, an inaccurate MSDS cannot

provide accurate information to rescuers, such as when a chemical is leaked, it

is difficult for rescuers to take effective countermeasures if it is not clear

about its hazard category and suitable fire extinguishing medium.

In the handling and storage process,

inaccurate MSDS can also prevent operators from operating correctly. For

example, for some chemicals that require special storage conditions, if the

MSDS is not accurately stated, it may lead to improper storage, which can lead

to chemical reactions and safety accidents. When it comes to exposure control

and personal protection, the wrong MSDS can lead workers to use inappropriate

protective equipment that prevents them from effectively protecting themselves

from chemical hazards.

For the measure of judging whether general

goods or dangerous goods are based on the appraisal certificate, although it

can make up for the inaccuracy of the manufacturer's self-compiled MSDS to a

certain extent, there are also some limitations. On the one hand, the

acquisition of an appraisal report may require additional time and cost; On the

other hand, there may be differences in standards and testing methods between

different accreditation bodies, which may also lead to inconsistencies in

judgment results.

To sum up, MSDS plays an indispensable role

in the production, transportation, storage and emergency treatment of chemical

products, but the current situation of inaccurate MSDS compiled by

manufacturers has seriously affected its function, and measures need to be

taken to improve the accuracy of MSDS to ensure the safety and orderly conduct

of related activities in the chemical industry.

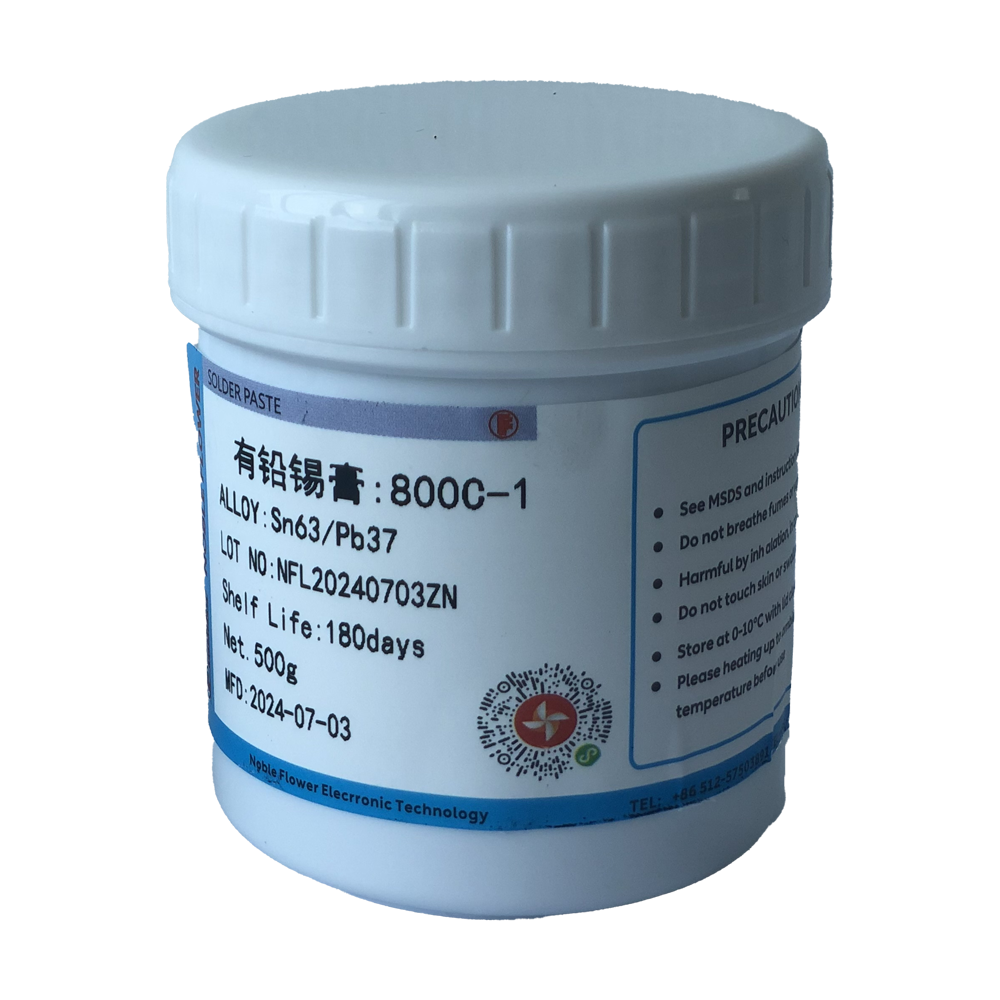

从事SMT SMD加工的朋友应该对焊膏并不陌生。购买时焊膏,他们经常被要求根据实际需要仔细选择类型,并与诺菲尔焊料制造商一起测试样品。这是一种非常重要的材料。那么,如此重要的材料起着什么作用呢?苏州诺伊菲尔德接下来为您解读:

20世纪70年代,表面贴装技术刚刚开始兴起,也称为SMT。这是一种印刷电路板焊盘印刷和涂覆焊膏技术,在涂覆焊膏的焊盘上精确地粘贴电子元件的表面,并根据特定的回流温度曲线加热电路板,使焊膏熔化。在其合金成分冷却并固化后,在元件和印刷电路板之间形成焊点,以实现焊接的电子元件连接。

焊膏是随着SMT技术的出现而出现的一种新型焊接材料。它是一种用于将零件的电极与电路板的焊盘连接起来的焊料,主要用于SMT行业,用于在PCB表面焊接电容器、电阻器和IC等电子元件。焊膏在室温下也有一定的粘度,可以暂时将电子元件粘在既定位置固定,在焊接温度下,随着溶剂和部分添加剂的挥发,焊膏首先熔化以固定引脚和焊接,待冷却后将电子元件和印刷电路焊盘焊接在一起,形成稳定的连接。

焊膏是一个复杂的系统,是将焊料粉末、助焊剂和其他金属添加剂混合成糊状,并改变其成分以满足不同产品的焊接需求。因此,组成焊膏的成分都有不同的作用。

焊膏的作用主要分为这些模块,首先是合金粉末的作用,是完成电子元件和电路板之间的机械和电气连接。

其次是助焊剂:它是锡粉颗粒的物质,提供适当的流变性和湿度,促进热量传递到焊接区域,降低焊料的表面张力,防止焊接过程中焊料和焊接表面的再氧化。其中,不同成分的作用如下:

1、溶剂(solvent):该组分是焊料组分的溶剂,在焊膏的混合过程中起着调节焊膏均匀性的作用,对焊膏的寿命有一定的影响;

2、树脂(Resins):该成分主要起到增加焊膏附着力的作用,还起到保护和防止焊料PCB在焊接后再次氧化的作用;该组件在固定的零件中起着非常重要的作用。

3、活化剂(Activation):该成分主要起到去除PCB铜膜焊盘表层和焊接部件氧化的作用,同时具有降低锡、铅表面张力的作用;

4、触变剂(thixotropic):该成分主要是调节焊膏的粘度和印刷性能,在印刷中起到防止拖尾、粘附等现象的作用;

作为一家拥有18年经验的焊膏制造商,诺菲尔电子技术 始终致力于焊膏的研发、生产和销售。我们的产品质量稳定,无连续锡,无虚焊,无裂纹;无锡珠残留,焊点光亮饱满,焊接牢固,导电性强。如果需要使用,您可以联系我们的技术,免费提供解决方案来解决您的问题!

翻译与www.DeepL.com/Translator(免费版本)

一些特殊类型的焊膏容易变干,一般的焊膏供应商都配备了特殊的溶剂——稀释剂。然而,对于某些品牌的焊膏,其本身并无重大质量问题,因此无法提供溶剂供您添加。下一步是为苏州Noble Flower焊膏厂家说几句话:

焊膏干燥后,切勿用水稀释。

锡膏绝对禁止与水混合,如果少量锡膏偶尔使用,可以与少量酒精混合,使用后搅拌均匀;如果锡膏的含量较大,则需要与特殊的稀释剂混合。

焊膏在储存和使用过程中总会产生化学反应,虽然这种反应是不可避免的,但合理设计的焊膏在正常使用条件下的反应速率应该相当缓慢,这样其使用寿命就足以满足正常生产需要。它可以用冷藏卡车运输,并使用冷冻机冷藏储存在工厂仓库中。容易变干的焊膏通常是配方设计缺陷的结果。此外,确保合规的操作环境和标准化的处理可以延长糊剂的寿命。其他因素,如使用过程中的溶剂蒸发,也可能影响使用寿命,但不是主要因素。

在使用焊膏的过程中,要严格遵守焊膏的使用规范,否则会影响焊膏本身的特性,导致焊接不良;那用什么牌子的焊膏比较好。

推荐Noble Flower无铅焊膏,用途广泛,环保焊膏专业人士放心,可以满足SMT生产的耐温有特殊焊接要求的产品。咨询客服人员,为您推荐高质量、价格优惠、价格便宜的焊膏产品,质量好、服务好是我们的优势!