MSDS (Material Safety Data Sheet), that is, the Safety Data Sheet of

Chemicals, can also be translated as Safety Data Sheets for Chemicals or Safety

Data Sheets for Chemicals. In European countries, MSDS is also known as SDS,

which is a document used by chemical manufacturers and importers to explain the

physical and chemical properties of chemicals (such as PH value, flash point,

flammability, reactivity, etc.) and possible harm to the health of users (such

as carcinogenicity, teratogenicity, etc.), containing a total of 16 contents.

1.Chemical

Product and Company Identification: It mainly indicates the name of the

chemical, the name of the manufacturer, the address, zip code, telephone

number, emergency telephone, fax and email address.

2.Information

on Hazardous Ingredients: Indicates whether the chemical is pure or a mixture,

including all hazardous substances containing more than 1% and carcinogens

exceeding 0.1%. If it is a pure chemical, the chemical name or trade name and

generic name should be given; In the case of mixtures, the concentration or

concentration range of the hazardous components should be given. Whether it is

a pure chemical or a mixture, if it contains a hazardous component, the

Chemical Abstracts Index Registry Number (CAS number) should be given.

3.Hazard

identification: Summarize the most important hazards of the chemical and its

impact on health, mainly covering hazard categories, invasion routes, health

hazards, environmental hazards, fire and explosion hazards and other

information.

4.First Aid

Measures: Self-help or mutual rescue methods (e.g., inhalation, ingestion, eye

contact, skin-to-skin treatment) in the event of an accidental injury.

5.Fire

Fighting Measures: It mainly displays the physical and chemical special hazards

of chemicals, suitable fire extinguishing media, unsuitable fire extinguishing

media, and personal protection of firefighters, including hazard

characteristics, fire extinguishing media and methods, fire extinguishing

precautions, etc.

6.意外泄露处置措施(Accidental

Release Measures):清理小型和大型泄漏的程序以及化学物质泄漏周围的具体规定。

7.Handling and

Storage: Provides information on the safe storage and safe use of materials.

8.Exposure

Control/Personal Protection: Protective methods and means used to protect

workers from chemical hazards in the process of producing, handling, handling

and using chemicals, including gloves, clothing, eye protection, and

respiratory protection.

9.Physical and

Chemical Properties: It mainly describes the appearance and physical and

chemical properties of chemicals, including appearance and properties, pH

value, boiling point, melting point, relative density (water = 1), relative

vapor density (air = 1), saturation vapor pressure, heat of combustion,

critical temperature, critical pressure, octanol/water partition coefficient,

flash point, ignition temperature, explosion limit, solubility, main uses and

some other special physical and chemical properties.

10.Stability

and Reactivity: Indicates stable substances, causes of instability and

incompatibility, including stability, prohibited substances, conditions under

which contact should be avoided, polymerization hazards, and decomposition

products.

11.Toxicology

Information: Provides toxicological information of chemicals, including acute

toxicity (LD50, LD50), irritation, sensitization, subacute and chronic

toxicity, mutagenicity, teratogenicity, carcinogenicity, etc.

12.Ecological

Information: It mainly states the environmental and ecological effects,

behaviors and outcomes of chemicals, including biological effects (such as

LD50, LD50), biodegradability, bioaccumulation, environmental transport and

other harmful environmental impacts.

13.Disposal

Considerations: refers to the safe disposal methods of chemical-contaminated

packaging and chemicals with no use value, including disposal methods and

precautions.

14.Transportation

Information: Mainly domestic and international chemical packaging,

transportation requirements and transportation regulations classification and

numbering, including dangerous goods number, packaging category, packaging

mark, packaging method, UN number and transportation precautions.

5.Regulatory

Information: Mainly legal provisions and standards for chemical management, as

well as CITES related EPA and OSHA regulations.

16.Other

Information: It mainly provides other information that is important to

security, such as references, time of filling in the form, department of

filling in the form, data review unit, etc.

In general, MSDS is used to determine

whether the goods are suitable for sea transportation and what appropriate mode

of transportation is used to ensure transportation safety. When booking a

specific cargo for export, the carrier (shipping company) will require an MSDS,

and all personnel who come into contact with or may come into contact with the

cargo (including loading and unloading personnel, depot/warehouse personnel,

etc.) will need an MSDS. Operators must follow the guidelines and instructions

of MSDS for correct operation and disposal, especially in emergencies such as

package damage and leakage, it is difficult to understand the situation without

MSDS, which will delay rescue, and blind action will lead to serious

consequences.

The 16 contents of the MSDS issued by

authoritative institutions are very accurate, for example, the Shanghai

Institute of Chemical Industry can issue them. But now basically the

manufacturer compiles the MSDS by itself, and the accuracy is not high, so many

times it is necessary to refer to the identification certificate to judge

whether it is ordinary goods or dangerous goods. In the actual trade and

transportation of chemical products, the accuracy of MSDS is extremely

critical. It is very common for manufacturers to compile their own MSDS

inaccurately, which makes there are many hidden dangers when judging the nature

of the goods. Since an inaccurate MSDS may not accurately reflect the

characteristics of chemicals, it may lead to misjudgment as to whether the

goods are suitable for sea transportation and what mode of transportation to

use.

When booking cargo, if the carrier is

acting on an inaccurate MSDS, it may transport the cargo that should have been

handled in accordance with the requirements for the transport of dangerous

goods as general cargo, or vice versa. Not only can this be a violation of

transport regulations, but it also poses a significant risk to transport

safety. For example, if an accident occurs during transportation, an inaccurate

MSDS cannot provide accurate information to rescuers, such as when a chemical

is leaked, it is difficult for rescuers to take effective response measures if

it is not clear about its hazard category and suitable fire extinguishing

medium.

Inaccurate MSDS can also prevent operators

from operating correctly during handling, disposal, and storage. For example,

for some chemicals that require special storage conditions, if the MSDS does

not accurately state, it may lead to improper storage, which can lead to

chemical reactions and safety accidents. When it comes to exposure control and

personal protection, the wrong MSDS can lead workers to use inappropriate

protective gear that prevents them from effectively protecting themselves from

chemical hazards.

For the measure of judging whether ordinary

goods or dangerous goods are made by referring to the appraisal certificate,

although it can make up for the inaccuracy of the manufacturer's self-compiled

MSDS to a certain extent, there are also some limitations. On the one hand,

obtaining an appraisal certificate can require additional time and cost; On the

other hand, there may be differences in standards and testing methods between

different accreditation bodies, which may also lead to inconsistencies in judgment

results.

To sum up, MSDS plays an indispensable role

in the production, transportation, storage and emergency treatment of chemical

products, but the current situation of inaccurate MSDS compiled by

manufacturers has seriously affected its function, and measures need to be

taken to improve the accuracy of MSDS to ensure the safety and orderly conduct

of related activities in the chemical industry.

In the actual trade and transportation of

chemical products, the accuracy of the MSDS is crucial. It is not uncommon for

manufacturers to compile their own MSDS inaccurately, which makes there are

many hidden dangers when judging the nature of goods. Since an inaccurate MSDS

may not accurately reflect the characteristics of chemicals, it may lead to

misjudgment as to whether the goods are suitable for sea transportation and

what mode of transportation to use.

When booking cargo, if the carrier relies

on an inaccurate MSDS, it may transport the cargo as general cargo that should

have been handled in accordance with the requirements for the transport of

dangerous goods, or vice versa. Not only can this be a violation of transport

regulations, but it also poses a significant risk to transport safety. For

example, if an accident occurs during transportation, an inaccurate MSDS cannot

provide accurate information to rescuers, such as when a chemical is leaked, it

is difficult for rescuers to take effective countermeasures if it is not clear

about its hazard category and suitable fire extinguishing medium.

In the handling and storage process,

inaccurate MSDS can also prevent operators from operating correctly. For

example, for some chemicals that require special storage conditions, if the

MSDS is not accurately stated, it may lead to improper storage, which can lead

to chemical reactions and safety accidents. When it comes to exposure control

and personal protection, the wrong MSDS can lead workers to use inappropriate

protective equipment that prevents them from effectively protecting themselves

from chemical hazards.

For the measure of judging whether general

goods or dangerous goods are based on the appraisal certificate, although it

can make up for the inaccuracy of the manufacturer's self-compiled MSDS to a

certain extent, there are also some limitations. On the one hand, the

acquisition of an appraisal report may require additional time and cost; On the

other hand, there may be differences in standards and testing methods between

different accreditation bodies, which may also lead to inconsistencies in

judgment results.

To sum up, MSDS plays an indispensable role

in the production, transportation, storage and emergency treatment of chemical

products, but the current situation of inaccurate MSDS compiled by

manufacturers has seriously affected its function, and measures need to be

taken to improve the accuracy of MSDS to ensure the safety and orderly conduct

of related activities in the chemical industry.

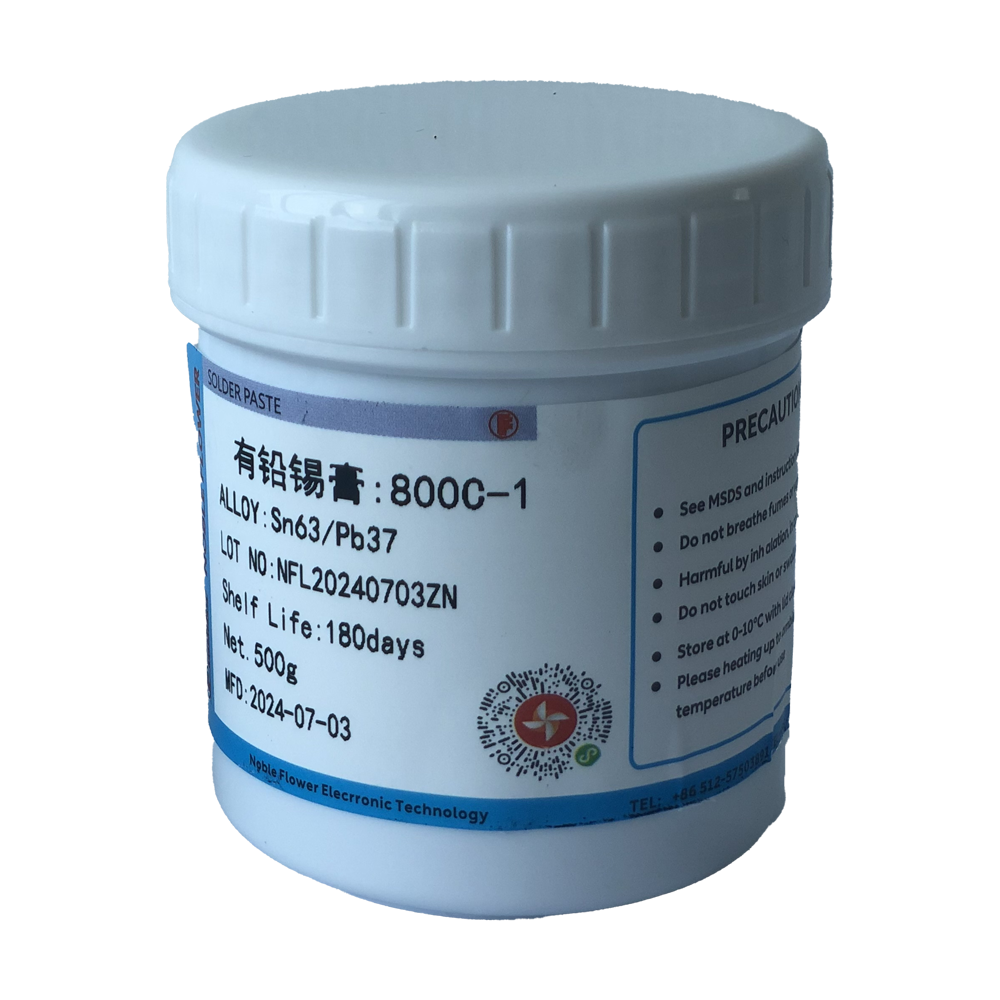

{\fnCandara\fs60\b1\4cH000000\4aH80}Teman-teman yang terlibat dalam proses SMT SMD seharusnya tidak ada orang asing untuk melekat. Saat membelipasta solder, mereka sering diminta untuk memilih tipe dengan hati-hati menurut kebutuhan sebenarnya dan menguji sampel dengan pembuat tentara Nofel. Ini adalah bahan yang sangat penting. Jadi, peran apa yang begitu penting? Suzhou Neufeld berikutnya untuk interpretasi Anda:

Pada tahun 1970-an, teknologi pegunungan permukaan baru saja mulai meningkat, juga dikenal sebagai SMT. Ini adalah pads papan sirkuit dicetak yang dicetak dan dikelilingi dengan teknologi pasta solder, dalam pads paste solder yang dikelilingi tepat melekat permukaan komponen elektronik, dan menurut profil suhu reflow spesifik untuk memanaskan papan sirkuit, sehingga pasta solder meleleh. Setelah komposisi legasinya dingin dan dikonsolidasi, sebuah kongsi solder terbentuk antara komponen dan papan sirkuit cetak untuk mencapai koneksi komponen elektronik soldered.

Pasta prajurit adalah jenis baru bahan prajurit yang muncul bersama dengan muncul teknologi SMT. Ini adalah semacam solder yang digunakan untuk menghubungkan elektroda bagian-bagian dengan pad papan sirkuit, dan terutama digunakan dalam industri SMT untuk soldering komponen elektronik seperti kondensator, resistor dan ICs di permukaan PCB. Pasta prajurit pada suhu kamar juga memiliki tingkat tertentu viskositas, dapat sementara menempel komponen elektronik di posisi yang ditetapkan tetap, dalam suhu penywelding, dengan solven dan bagian dari volatilisasi aditif, pasta prajurit terlebih dahulu meleleh untuk memperbaiki pins dan soldering, untuk mendinginkan setelah komponen elektronik dan pads sirkuit cetak penywelded bersama-sama untuk membentuk koneksi stabil.

Pasta Solderadalah sistem kompleks, adalah campuran bubuk solder, aliran dan aditif logam lainnya ke dalam pasta, dan mengubah komposisinya untuk memenuhi kebutuhan solder dari produk yang berbeda. Oleh karena itu, komponen yang membuat pasta tentara semua memiliki peran yang berbeda.

Peran pasta solder terutama dibagi ke modul-modul ini, yang pertama adalah peran serbuk liga, adalah menyelesaikan koneksi mekanik dan listrik antara komponen elektronik dan papan sirkuit.

Kedua, ada aliran: itu adalah substansi partikel bubuk tin, yang menyediakan reulogi dan kemudahan yang tepat, memudahkan pemindahan panas ke area perang, mengurangi ketegangan permukaan tentara, dan mencegah re-oksidasi tentara dan permukaan perang selama perang. diantara mereka, peran komponen berbeda adalah seperti ini:

1, solven (Solvent): Komponen adalah solven komponen solder, dalam proses campuran pasta solder bermain peran dalam mengatur keseluruhan hidup pasta solder memiliki dampak tertentu;

2, resin (Resins): komponen terutama memainkan peningkatan pada pegangan pasta solder, tetapi juga untuk melindungi dan mencegah peran oksidasi PCB solder lagi setelah penywelding; komponen ini bermain peran yang sangat penting dalam bagian yang tetap.

3, aktivator (Aktivasi): Komponen ini terutama bermain peran untuk menghapus lapisan permukaan pad film tembaga PCB dan bagian oksidasi bagian-bagian yang ditelan, dan pada saat yang sama memiliki efek untuk mengurangi ketegangan permukaan tin, lead;

4, agen thixotropic (Thixotropic): komponen adalah terutama untuk mengatur viskositas pasta solder dan prestasi cetakan, untuk bermain peran dalam cetakan untuk mencegah fenomena menarik ekor, adhesi dan sebagainya;

Sebagai pembuat pasta tentara veteran berusia 18 tahun,Teknologi Elektronik Nofil selalu berkomitmen untuk penelitian dan pengembangan, produksi dan penjualan pasta prajurit. Produk kami kualitas stabil, tidak ada tin terus menerus, tidak ada tentara palsu, tidak ada retak; tidak ada sisa kacang tin, arti solder yang cerah dan penuh, penywelding yang kuat, konduktivitas yang kuat. Jika perlu digunakan, Anda dapat menghubungi teknologi kami, gratis untuk menyediakan solusi untuk memecahkan masalah Anda!

Terjemahan dan www.DeepL.com/Translator (versi gratis)

Beberapa jenis spesial pasta solder cenderung untuk kering keluar, dan pemasok paste solder umum dipersediakan dengan solven spesial - lebih tipis. Namun, untuk beberapa merk pasta solder, tidak ada masalah kualitas besar sendiri, sehingga mereka tidak dapat menyediakan penyelesaian untuk Anda menambahkan. Langkah berikutnya adalah untuk Suzhou Noble Flower prajurit memasang pasta untuk mengatakan beberapa kata:

Ketika pasta solder kering, jangan pernah dilusi dengan air.

Pasta tinya benar-benar dilarang untuk mencampur dengan air, jika sejumlah kecil pasta tinya untuk digunakan kadang-kadang, dapat dicampur dengan sejumlah kecil alkohol, bergetar dengan baik setelah digunakan; jika isi pasta tin besar, harus dicampur dengan penapis khusus.

Pasta peneliti dalam penyimpanan dan penggunaan proses akan selalu menghasilkan reaksi kimia, meskipun reaksi ini tidak dapat dihindari, tetapi paste peneliti yang cukup dirancang dalam penggunaan normal kondisi tingkat reaksi seharusnya cukup lambat, sehingga hidup layanannya cukup untuk menghadapi kebutuhan produksi normal. Ini dapat dipindahkan dalam truk pendingin dan disimpan di gudang pabrik menggunakan beku untuk pendinginan. Pasta Solder yang susah untuk kering sering adalah hasil dari cacat dalam desain formulasi. Selain itu, memastikan lingkungan operasi yang sesuai dan pengurusan standar dapat memperpanjang hidup paste. Faktor lain, seperti evaporasi solven selama penggunaan, juga mungkin memiliki efek pada kehidupan layanan, tetapi bukan faktor utama.

Dalam penggunaan pasta solder dalam proses, untuk menjaga spesifikasi untuk menggunakan pasta solder, jika tidak akan mempengaruhi karakteristik pasta solder sendiri, yang berasal dari prajurit yang buruk; bahwa untuk menggunakan merk paste prajurit yang lebih baik.

Direkomansikan Noble Flower pasta prajurit bebas plum, jangkauan luas penggunaan, prajurit perlindungan lingkungan paste profesional untuk istirahat yakin bahwa dapat memenuhi produksi SMT resistensi suhu memiliki keperluan penywelding khusus produk. Konsultasi staf layanan pelanggan, untuk Anda untuk merekomendasikan kualitas tinggi, harga yang baik dan produk paste prajurit murah, kualitas yang baik dan layanan yang baik adalah keuntungan kami!

Su Gongwang Security 32058302004438

Su Gongwang Security 32058302004438