Замечания:1 创始人: Site Editor Publish Time: 2025-12-26 Origin: Веб - сайт

In-Depth Analysis of Key Points in SMT

Solder Paste Printing Process

With the rapid development of the

electronics manufacturing industry, surface mount technology (SMT) is

continuously advancing toward component miniaturization and high-density

assembly. This trend imposes increasingly stringent requirements on the solder

paste printing process. As a critical pre-process in the SMT production flow,

the quality stability of Сварочная паста printing directly determines the

first-pass yield of subsequent soldering and the overall reliability of the

product. To achieve high-level soldering quality, enterprises must precisely

control every aspect of the solder paste printing process. This article will

systematically analyze the key control elements in the solder paste printing

process from multiple dimensions, including solder paste characteristics,

substrate requirements, stencil parameters, and squeegee selection.

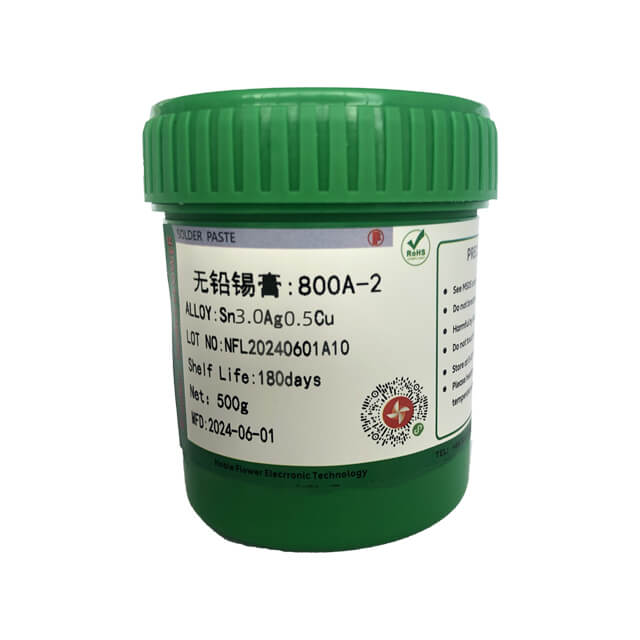

Composition and Mechanism of Solder Paste

As the core material in the SMT process, solder paste is a paste system formed by the precise mixing of solder powder, flux, and various additives (such as surfactants and thixotropic agents). At room temperature, its unique thixotropic properties provide moderate adhesion, temporarily fixing electronic components to the preset positions on PCB pads. During the reflow soldering process, as the temperature rises, solvents and volatile components in the flux gradually evaporate, and the solder powder particles form continuous solder joints in a molten state, ultimately achieving stable electrical and mechanical connections between the components and the printed circuit board.Сварочная паста fulfills three core functions in electronic assembly, all of which are indispensable: Electrical Connection: The alloy components in the solder powder (such as common Sn-Pb and Sn-Ag-Cu systems) form conductive pathways after melting, ensuring efficient transmission of electronic signals between components and the circuit board. Thermal Conduction: The metal connection layer formed by the solder joints rapidly conducts heat generated during component operation to the PCB substrate, effectively preventing equipment failure caused by localized overheating.

Mechanical Fixation: The solidified solder

joints securely lock components in place through metallic bonding forces,

resisting mechanical stresses such as vibration and impact, and ensuring

structural stability during long-term use.

In terms of application scenarios, solder paste, with its high-precision dispensing characteristics, is the preferred material for soldering fine-pitch components (such as 0201 packaged chip resistors and BGA chips). It is widely used in high-density circuit assembly areas, including smartphones, communication base stations, and medical equipment. Its technical advantages are reflected in: Micron-level printing precision adaptable to pad designs with pitches below 0.3mm; Combined with fully automatic printers and reflow ovens, achieving mass production efficiency of thousands of PCBs per hour; Optimized flux formulations effectively inhibit solder joint oxidation, significantly reducing the risk of cold soldering.

Analysis of Key Control Points in Solder Paste Printing Process Control of Solder Paste Performance Parameters The physical characteristics of solder paste directly affect printing results, with key indicators including: Viscosity: Should be maintained within the range of 80,000-120,000 cP at room temperature (adjusted according to printing speed); excessive viscosity fluctuations can lead to insufficient solder or collapse; Solder Powder Particle Size: For pads with pitches below 0.5mm, ultra-fine powder of 20-38Мm should be selected to avoid clogging stencil apertures; Flux Activity: Select RMA or RA grade active flux based on PCB surface treatment processes (such as OSP and ENIG) to prevent pad oxidation. The storage and usage specifications of Сварочная пастаare equally critical: unopened products must be stored refrigerated at 2-10°C, require tempering for over 4 hours before use, and thorough stirring to avoid bubble formation due to sudden temperature changes.

Quality Requirements for Printing

Substrates

As the printing carrier, the geometric accuracy and surface condition of the PCB substrate significantly impact printing quality: Dimensional Stability: Substrate warpage must be controlled within 0.75%, otherwise, it will lead to poor stencil adhesion; Pad Cleanliness: Oxidation layers and oil stains must be removed through plasma cleaning or alcohol wiping to ensure solder wettability; Solder Mask Accuracy: The misalignment between the solder mask opening edges and the pads should be ≤25Мm to prevent solder paste overflow. Production practice shows that using thickened substrates (thickness ≥1.6mm) combined with rigid support can reduce printing offset by over 30%.

Stencil Parameter Optimization

As the key mold for solder paste transfer, the design parameters of the stencil must precisely match product characteristics: Thickness Selection: Based on solder joint height requirements, 0402 components correspond to 0.12mm stencils, while BGA solder joints require 0.15-0.2mm; Aperture Design: Using stepped apertures (reduced by 5% in fine-pitch areas) can reduce bridging; the diameter of circular apertures should be 10% smaller than the pad; Inner Wall Smoothness: Achieve aperture Ra ≤0.8Мm through electropolishing to reduce solder paste residue risk. Statistical data indicate that using nano-coated stencils can extend the cleaning cycle to 50 boards/time, significantly improving production efficiency.

Squeegee System Configuration

The material and operating parameters of the squeegee directly determine the solder paste dispensing effect: Material Selection: Polyurethane squeegees (hardness 70-80 Shore A) are suitable for ordinary components, while metal squeegees are used for pitches below 0.3mm; Angle Control: The contact angle between the squeegee and the stencil should be maintained at 45°-60°; excessive angles can lead to excessive solder paste residue; Pressure Adjustment: Initial pressure is set at 0.15-0.2MPa, with gradual fine-tuning (±0.02MPa each time) based on printing results. A case study from an enterprise shows that using diamond-shaped cross-section squeegees can improve Сварочная паста thickness consistency to ±5Мm.

Printing Support System Design

A reasonable support scheme can effectively eliminate substrate deformation: Pin Layout: Place one 5mm diameter pin every 100mm along the long side of the substrate to form a uniform support matrix;

Support Plate Application: For flexible substrates, using perforated support plates (30% perforation rate) can reduce stress concentration; Vacuum Adsorption: Adsorption force controlled between -40 and -60kPa to prevent substrate shifting during printing. Simulation tests show that an optimized support system can control the gap between the PCB and the stencil within 5Мm.

Collaborative Optimization of Printing

Parameters

The matching between parameters is more critical than the accuracy of a single parameter: Printing Speed: Use 20mm/s for fine-pitch areas, and increase to 50mm/s for ordinary areas; excessive speed can cause bubbles; Separation Parameters: Separation speed set to 1/3 of the printing speed, separation distance controlled at 0.5-1mm to reduce solder paste stringing; Cleaning Frequency: Perform wet wiping + dry wiping every 10-15 prints, using dedicated stencil cleaning agents (containing 5% alcohol). DOE experiments show that when the printing speed is 30mm/s, pressure is 0.18MPa, and separation speed is 10mm/s, the printing yield can reach 99.2%.

Control of Solder Paste Volume

The rolling state of solder paste on the stencil is an important indicator for quality monitoring: Rolling Diameter: Maintain a cylindrical roll of 15-20mm; too small leads to insufficient filling, too large causes waste;

Replenishment Frequency: Replenish promptly when the roll length is less than 2/3 of the stencil width to avoid frequent printing interruptions; Stirring Requirements: Manually stir for 10 seconds with a dedicated tool after each replenishment to fully mix old and new solder paste. In actual production, using an automatic solder paste dispensing system can improve printing weight stability by 20%.

Application of Optical Alignment Systems

High-precision alignment is a prerequisite for fine-pitch printing: Recognition Accuracy: Camera resolution ≥1200dpi, ensuring recognition error of 0.1mm markers ≤1Мm;

Compensation Mechanism: Establish a temperature compensation model (0.5Мm compensation per °C) to eliminate thermal deformation effects;Calibration Cycle: Perform baseline calibration before each shift, ensuring X/Y direction deviation ≤2Мm. The dual-camera alignment system of a high-end printer can reduce alignment time to 2 seconds/board, with repeatability accuracy of ±1.5Мm.

Process Collaboration and Quality

Improvement Pathways

Quality control of the solder paste

printing process requires establishing a full-factor collaboration mechanism:

when switching to smaller components, the three parameters of stencil aperture,

squeegee pressure, and printing speed must be adjusted simultaneously; for

high-warpage substrates, the support system should be optimized first rather

than simply increasing printing pressure. It is recommended that enterprises

establish a printing process database to record the best parameter combinations

for different products, enabling intelligent recommendation of process

parameters through big data analysis.

With the development of advanced packaging technologies such as Mini LED and SiP, Сварочная паста printing is moving toward the goals of "sub-micron precision" and "zero defects." In the future, by introducing 3D SPI real-time detection (accuracy ±1Мm) and AI visual defect classification technologies, closed-loop control of printing quality can be achieved, providing core support for the continuous upgrade of SMT processes.

Безопасность сети 32058300438

Безопасность сети 32058300438