Замечания:1 创始人: Site Editor Publish Time: 2025-12-29 Origin: Веб - сайт

In the transition of the electronics

manufacturing industry toward lead-free processes, traditional lead-based

processes coexist with new lead-free components, creating a complex process

environment. Among these, the mixed assembly soldering of lead-free BGAs and

leaded components has become a typical challenge in process integration. This

technological intersection not only involves matching material characteristics

but also tests the synergy capability of the entire production chain—from micron-level precision control in PCB layout design to managing

temperature fluctuations of ±1°C

during soldering. Even minor deviations in each step can lead to an

order-of-magnitude decrease in product reliability. Based on the stringent

quality standards of aerospace and military products and incorporating data

from thousands of production batches, this paper establishes a full-process

quality control system covering design, materials, processes, and inspection,

providing a systematic solution for high-reliability electronic assembly.

Microstructural Optimization and Process

Adaptation in PCB Design

As the soldering carrier, the design

quality of the PCB directly determines the process window for mixed assembly of

lead-free BGAs. In thermal management design, the use of "zonal thermal

resistance regulation" technology significantly improves soldering

temperature uniformity: dividing the PCB into a core heating zone (BGA area),

transition zone (within 3mm surrounding area), and peripheral zone. Through a

gradient design of copper foil thickness (105Мm in the

core zone, 70Мm in the transition zone, 35Мm in the peripheral zone), the temperature difference during

soldering is controlled within 3°C. Practice in an

aerospace product shows that this design can reduce the voiding rate of BGA

solder joints from 12% to below 5%.

Fluid dynamics optimization of pad

morphology is crucial: The aspect ratio of elliptical pads, verified by fluid

simulation, shows that 1.5:1 is the optimal value. At this ratio, the flow rate

of molten solder increases by 27% compared to circular pads. For BGA soldering

with a 0.8mm pitch, the copper exposure defect rate can be controlled below

0.3%; The solder mask opening for SMD pads adopts a "stepped slope"

design, forming a gentle slope 0.1mm high outward from the pad edge. This

structure increases gas escape speed by 40%, reducing the number of voids

larger than 50Мm in diameter by 65% in SnAgCu solderball soldering; For large component pads on side A in double-sided soldering,

setting a 0.2mm wide solder mask dam with a 0.1mm deep annular groove can

reduce the lifting force of solder joints from 8N in traditional designs to

2.5N, fully meeting military vibration test requirements (10Hz~2000Hz, 20g

acceleration).

Process details in via treatment determine

soldering reliability: Plated-through holes for through-hole components use a

"tapered hole" design, with an entrance diameter 0.25mm larger than

the pin and an exit diameter 0.2mm larger. This structure achieves a solder

fill height of over 85% of the hole depth, a 15% improvement over straight-hole

designs; Blind vias under BGA pads use laser drilling, with hole mouth flatness

error controlled within 3Мm and hole wall roughness Ra ≤ 0.4Мm, avoiding uneven solder accumulation

caused by traditional mechanical drilling; Vias in the wave soldering area

undergo "resin filling + electroless nickel plating" dual sealing.

The thermal expansion coefficient matching between the filling resin and the

FR-4 substrate must reach over 95% (difference ≤ 5×10⁻⁶/°C),

ensuring no cracks occur during -55°C to 125°C temperature cycling.

Rework compatibility design must consider

multi-scenario requirements: Within a 5mm gap in the hot air rework area, no

components taller than half the BGA height should be placed, and Ф3mm positioning holes for the hot air nozzle must be reserved; In

the 0.5mm gap for laser rework areas, low-profile components (height ≤ 1mm) are allowed, but copper foil in the laser path must be

blackened to reduce reflectivity and improve heating efficiency; BGAs larger

than 15mm×15mm should have four fiducial marks (two on

each diagonal), using an "outer circle inner square" structure (outer

Ф1mm circle + inner 0.5mm square), achieving a rework

alignment accuracy of ±0.03mm.

Precision Management System for the Full

Lifecycle of Materials

Material management for mixed assembly of

lead-free BGAs requires establishing a "gene-level" traceability

system to eliminate mixing risks from the source. Components adopt a

"three-dimensional identification" system: body laser marking

(including Pb-free symbol), packaging QR code (storing material certificates,

batch test data), and tray color coding (green for lead-free devices, blue for

leaded). Implementation data from a military enterprise shows this

identification system can reduce mixing error rates from 0.05‰ to 0.001‰.

Microclimate control of the storage

environment is particularly critical: Temperature and humidity in the lead-free

device storage area are monitored in real-time (10°C~35°C / 40%~70% RH), with data recorded three times daily. Automatic

alarms trigger when deviations exceed ±2°C or ±5% RH; Shelving uses anti-static

materials with a layer spacing ≥ 150mm to ensure good

ventilation, and the bottom shelf is ≥ 300mm from the

floor to prevent ground moisture effects; Components opened from packaging must

be soldered within 48 hours. Unused devices exceeding this time must undergo

solderability retesting (according to GJB360B method 2026) before reuse.

PCB substrate selection follows the

"temperature-reliability" matching principle:

For products with peak temperatures below

240°C, use high heat-resistant FR-4 with Tg150°C (e.g., Isola FR408), whose heat deflection temperature (HDT) is ≥ 180°C, maintaining 90% mechanical strength

after 100 soldering cycles; For products in the 240°C~250°C range, use FR-5 substrate (e.g., Panasonic R-1515), whose glass

transition temperature is 20°C higher than FR-4 and

thermal conductivity is 15% higher; Military high-frequency products recommend

using polytetrafluoroethylene (PTFE) substrates (e.g., Rogers RO4350), whose

dielectric constant stability (change rate ≤ 0.5%) at

250°C soldering temperature is far superior to epoxy

substrates.

Metallurgical compatibility control of pad

plating:

Pb-Sn Hot Air Solder Leveling (HASL)

plating thickness is controlled between 1.2Мm~2.5Мm, with pad surface roughness Ra ≤ 1.6Мm. Its bonding strength with Sn63Pb37 solder paste can reach 22N, 5%

higher than Electroless Nickel Immersion Gold (ENIG); Electroplated Ni/Au

should have a nickel layer thickness of 5Мm~8Мm (ensuring sufficient diffusion barrier capability), and the gold

layer is strictly controlled between 0.05Мm~0.15Мm. Excessively thick gold layers increase solder joint brittleness;

when the gold layer reaches 0.3Мm, shear strength

decreases by 30%; Mixed plating designs like "one side HASL + one side

ENIG" are prohibited, as they can cause a thermal absorption difference of

up to 8% during double-sided reflow, leading to uneven temperature distribution

for BGA solder joints.

Synergistic optimization of solder and

flux:

The metal content of Sn63Pb37 solder paste

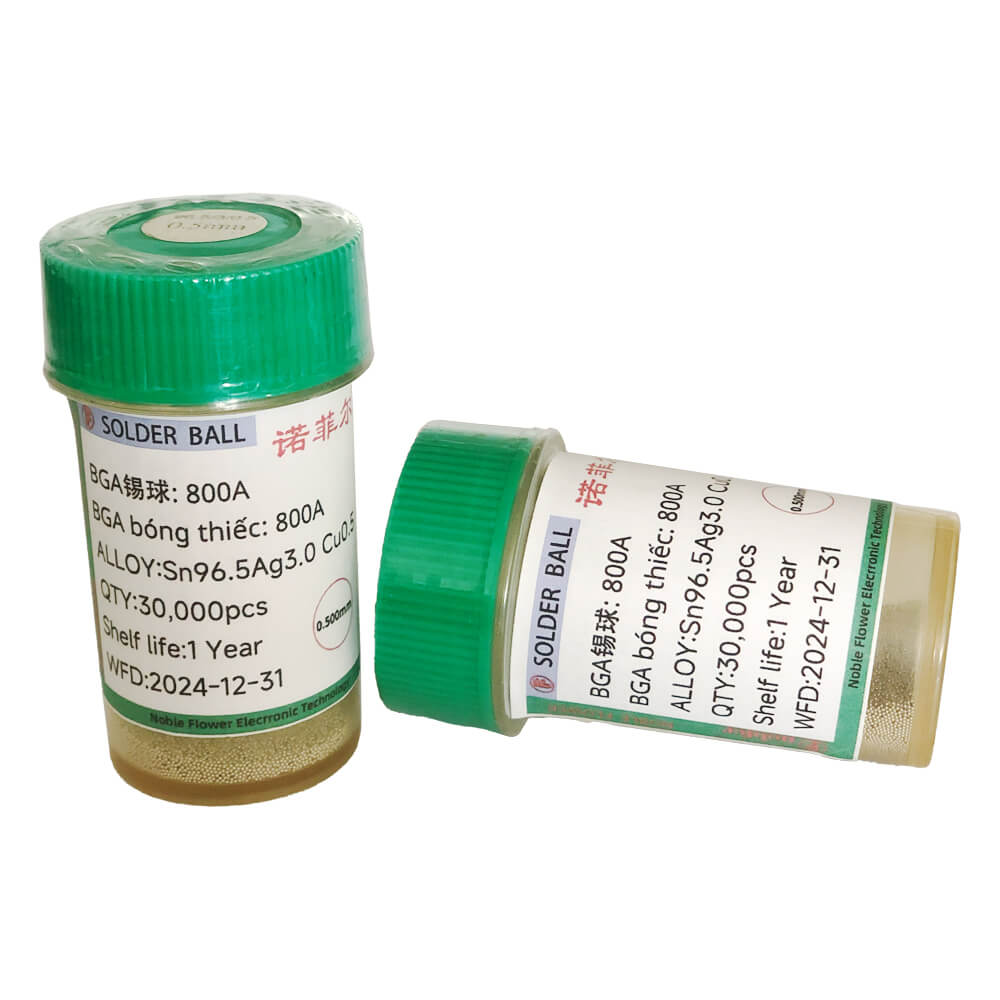

is controlled at 90%±1%. For BGAs with a 0.5mm pitch,

use Type 4 powder (20Мm~38Мm)

with sphericity ≥ 0.85 and spreadability ≥ 85% in solderability tests; Hand-soldering solder wire uses a

"multi-core" structure (outer layer Sn63Pb37, inner layer containing

2.3% RMA flux). For 0.6mm diameter wire soldering 0.8mm pitch joints, the

bridging rate can be controlled below 0.1%; Wave soldering flux with 0.3%

silicone modifier reduces surface tension to 28mN/m, maintains 80%

spreadability at 260°C, and the post-soldering residue

insulation resistance is ≥ 10¹¹Ω.

Precision Control Technology for the

Temperature Field in Mixed Assembly Soldering

Mixed assembly soldering of lead-free BGAs

and leaded components requires establishing a "dynamic temperature

compensation" system, ensuring optimal temperature ranges in all areas

through real-time monitoring and feedback adjustment. Reflow ovens should use

10-zone hot air vacuum type equipment (e.g., Heller 1913 MKIII), with

temperature control accuracy of ±0.5°C in upper and lower heating zones, transverse temperature

difference on the conveyor belt ≤ 1°C. Combined with nitrogen protection (oxygen content ≤ 500ppm), this can control the IMC layer thickness of solder joints

within the ideal range of 1Мm~2Мm.

Segmented precise setting of the

temperature profile:

- Preheating zone (80°C~150°C) uses a "stepped heating"

mode: heating rate of 1°C/s from 80°C~120°C, and 0.8°C/s

from 120°C~150°C, minimizing

thermal stress on the PCB and components. One test showed this method reduced

MLCC cracking rate from 2% to 0.3%; Soak zone (150°C~183°C) is maintained for 50s, achieving over 90% flux activation,

effectively removing oxide layers (thickness ≤ 5nm)

from pad surfaces; Reflow zone uses "peak temperature zonal control":

240°C±2°C for lead-free BGA areas, ≤ 230°C for leaded component areas, achieving temperature difference

control through local hot air adjustment. Time above liquidus is strictly

controlled at 60s±5s.

Differentiated temperature control

strategies for different components:

When a PCB contains both lead-free BGAs and

leaded QFPs, install an independent water-cooled cooling module under the QFP

area, keeping its temperature 12°C lower than the BGA

area. This ensures complete melting of Сварочный шар BGAs while preventing

overheating oxidation of QFP leads; Set a "thermal barrier" (copper

foil clearance) within a 3mm range around heat-sensitive components like

tantalum capacitors, combined with low-power heating, to control soldering

temperature between 220°C~225°C,

well below their 260°C heat resistance limit; For

double-sided reflow, solder small components on side B first (mass/area ratio ≤ 25g/in²), then solder large components on

side A. During the second soldering, the bottom temperature should be 25°C lower than the top. Through thermal simulation optimization, the

secondary melting rate of side B solder joints can be controlled below 5%.

Special soldering control for lead-free

BGAs:

BGAs with SnAgCu solder balls use a

"backward compatible profile," maintaining a 240°C peak temperature for 20s to ensure complete melting of solder

balls and thorough mixing with leaded solder paste, forming a uniform

Sn-Pb-Ag-Cu quaternary alloy. Solder joint shear strength can reach over 35MPa;

For lead-free components with Sn-plated terminations, soldering at 230°C forms

a continuous Cu₆Сн.₅ IMC layer about 1.5Мm thick, with interface

bonding strength 15% higher than soldering at 220°C; Components with Ag/Pd/Au plating require

maintaining 235°C

for 30s to promote diffusion reactions between precious metals and solder. For

example, Pd plating under these conditions can form PdSn₄ intermetallic compounds, avoiding brittle phase formation.

Mechanism Analysis and Systematic

Prevention of Cold Solder Defects

Cold solder, a critical defect in mixed

assembly soldering, is directly related to uneven spatiotemporal distribution

of heat supply. High-speed camera observation (1000 frames/s) reveals that

normal BGA solder joints undergo two characteristic collapse stages: Stage 1

(around 217°C): solder ball diameter increases by 35%,

in a semi-molten state; Stage 2 (240°C): solder ball

height decreases by 50%, forming a bright truncated cone-shaped solder joint.

Cold solder joints only complete Stage 1, failing to enter Stage 2 due to

insufficient heat, resulting in incomplete IMC layer development (thickness ≤ 0.5Мm), an orange peel-like surface, and

shear strength only 40% of normal joints.

Three-dimensional control system for cold

solder prevention: Temperature Verification: Use 3 thermocouples (BGA center,

edge, PCB backside) for real-time monitoring of the first piece per batch,

ensuring temperature difference ≤ 3°C and peak temperature ≥ 238°C. One company reduced the cold solder rate from 5% to 0.5% using

this method; Solder Paste Printing: Control solder paste printing thickness for

lead-free BGAs at 110Мm±5Мm. Stencil apertures use a "center-edge gradient design"

(center 5% smaller than edge) to compensate for thermal shrinkage differences

during soldering, improving solder paste distribution uniformity by 20%;

Equipment Maintenance: Calibrate the hot air circulation system weekly to

achieve wind speed uniformity ≥ 95%. Clean flux residue

inside the oven chamber monthly (thickness ≤ 0.1mm) to

prevent heating efficiency degradation due to increased thermal resistance.

Multi-dimensional Inspection System for

Solder Joint Quality

Quality inspection of mixed assembly solder

joints for lead-free BGAs requires a comprehensive

"optical-mechanical-electrical" evaluation: 3D SPI Inspection:

Measures solder joint collapse height (should be 45%~55% of original solderball diameter), surface roughness Ra ≤ 0.6Мm, and offset ≤ 20% of pad diameter. These

parameters show strong correlation (R²=0.92) with

solder joint reliability; X-ray Inspection: Uses equipment with 20Мm resolution. Single solder joint void area ≤ 12%, average void rate per device ≤ 8%.

Voids larger than 100Мm in diameter or continuous void

chains are prohibited; Ultrasonic Inspection: C-SAM equipment can detect

micro-cracks (length ≥ 5Мm)

inside solder joints, ensuring no potential failure risks. Military-grade

standards for reliability verification: Temperature Cycling: -55°C~125°C, 1000 cycles. No cracks in solder

joints after testing, shear strength retention ≥ 85%,

significantly higher than the 70% requirement for commercial products; Damp

Heat Test: 40°C/95% RH, 1000 hours. Insulation

resistance ≥ 10¹¹Ω, no

electrochemical migration (dendritic growth ≤ 10Мm); Vibration Test: 10Hz~2000Hz, 20g acceleration, 6 hours duration.

No solder joint detachment, resistance change rate ≤

5%.

Special reliability control for MLCCs:

Design: Connect pads to large-area ground copper foil via 0.3mm wide

"thermal buffer" traces, reducing thermal stress during soldering by

40%; Process: Avoid via-in-pad design. If necessary, use "resin plugging +

plating fill" process, with hole mouth flatness error ≤ 2Мm; Screening: Use both C-SAM and SLAM

inspection to eliminate MLCCs with internal micro-cracks (length ≥ 10Мm). Screening pass rate must be ≥ 99.8%.

Intelligent Process Upgrade and Future

Technology Directions

Mixed assembly soldering of lead-free BGAs

is moving towards "digital twin" development, achieving full-process

optimization through virtual soldering models: Machine learning-based

temperature profile prediction systems can automatically generate optimal

parameters based on PCB design and component distribution, reducing

trial-and-error costs by 60%; Online visual inspection systems (5Мm resolution) combined with AI algorithms can identify 99.9% of

defects like cold solder and voids in real-time and automatically adjust

process parameters; Digital traceability platforms record full-process data

from design to soldering, supporting quality traceback and analysis throughout

the product lifecycle.

New material technologies offer

possibilities for breakthroughs in mixed assembly processes:

Low-silver lead-free solder paste

(SnAg1Cu0.5) with a melting point reduced to 217°C

offers better compatibility with leaded processes, reducing thermal shock on

leaded components. One test showed it reduced QFP lead oxidation by 30%;

Nano-composite flux with added graphene (0.5% content) increases solder joint

thermal conductivity by 45%, lowering operating temperature by 10°C~15°C; Biodegradable flux using natural

plant extracts can completely dissolve in 60°C water

within 30 minutes, with residue ≤ 0.1mg/cm², meeting high cleanliness requirements.

Безопасность сети 32058300438

Безопасность сети 32058300438