Замечания:1 创始人: Site Editor Publish Time: 2026-01-04 Origin: Веб - сайт

Technical Characteristics and Industry Application Panorama of Laser Solder Jet Welding Systems

Against the backdrop of the rapid evolution of electronic manufacturing technology towards high precision and micro-joining, laser solder jet welding systems, as a revolutionary joining technology, are gradually breaking through the limitations of traditional welding processes in the field of precision manufacturing. By organically combining precise control of laser energy with solder ball jetting technology, this system achieves a leap from millimeter-scale to micrometer-scale welding, providing key support for the technological upgrade of the electronic information industry. According to the "2024 Electronic Manufacturing Technology Development Report" by the Chinese Institute of Electronics, adopting laser solder jet welding technology can increase the welding yield of electronic components to over 99.8%, reduce material loss by 30% compared to traditional wave soldering processes, while controlling energy consumption to within 50% of traditional equipment. This advanced manufacturing technology, which combines high precision, high efficiency, and environmental characteristics, not only helps domestic electronic processing enterprises achieve cost optimization and technological breakthroughs but also becomes one of the core equipment supporting the deep implementation of the Industry 4.0 strategy in the field of electronic manufacturing. The excellent performance of the laser solder jet welding system stems from its multi-dimensional collaborative technical architecture, forming a complete high-precision welding solution from mechanical motion control to optical energy regulation.

Motion Control System of Multi-Axis Intelligent Work Platform

The system's core actuator adopts a 7-axis linkage intelligent work platform, with each axis motion resolution reaching 0.001mm and repeat positioning accuracy ≤ ±0.005mm, ensuring precise positioning of solder ball jetting in three-dimensional space. Its technical characteristics are as follows: Dynamic Response Performance: The maximum motion speed of each axis can reach 500mm/s, with an acceleration of 200mm/s², enabling rapid completion of complex trajectory welding path planning; Load Adaptability: The worktable has a maximum load capacity of 5kg, compatible with various workpieces from micro-sensors (1mm×1mm) to medium-sized printed boards (300mm×300mm); Thermal Stability Design: Utilizes a marble base (thermal expansion coefficient ≤0.5ppm/°C) and a servo motor temperature feedback compensation system, maintaining positioning accuracy deviation ≤0.003mm even when the ambient temperature changes by ±5°C.

The synchronously integrated CCD positioning and monitoring system forms a closed-loop control chain of "measurement-feedback-correction": Visual Positioning Module: Equipped with a 2-megapixel industrial camera and a telecentric lens, with an image acquisition frame rate of 30fps, capable of recognizing positioning marks as small as 0.01mm; Image Processing Algorithm: Employs sub-pixel edge detection technology, achieving a positioning accuracy of 0.001mm, ensuring the alignment deviation between the solder ball jetting position and the pad is ≤0.005mm; Real-time Monitoring Function: Continuously collects molten pool images during the welding process, identifies abnormal states (such as solder ball deviation, lack of fusion, etc.) through AI algorithms, with a response time ≤10ms, enabling immediate alarm triggering or shutdown protection.

Core Process Characteristics of Solder Ball Jet Welding

This system adopts non-contact solder ball jetting technology, achieving instantaneous melting and welding of solder balls through focused laser beam energy. Its process advantages are reflected in multiple dimensions: Precision Control System: Solder ball diameter range covers 350Мm-760Мm, allowing precise matching according to solder joint size (diameter deviation ≤±5Мm); Single ball welding positioning accuracy ±0.01mm, solder volume control deviation ≤3%, ensuring the forming consistency of micro solder joints (minimum 0.3mm×0.3mm); Cross-section test data shows that the solder joint cold solder rate is only 0.2%, far lower than the 2% of traditional reflow soldering, and the IMC (intermetallic compound) layer thickness is controlled within the ideal range of 1-2Мm.

Thermal Effect Management Technology:

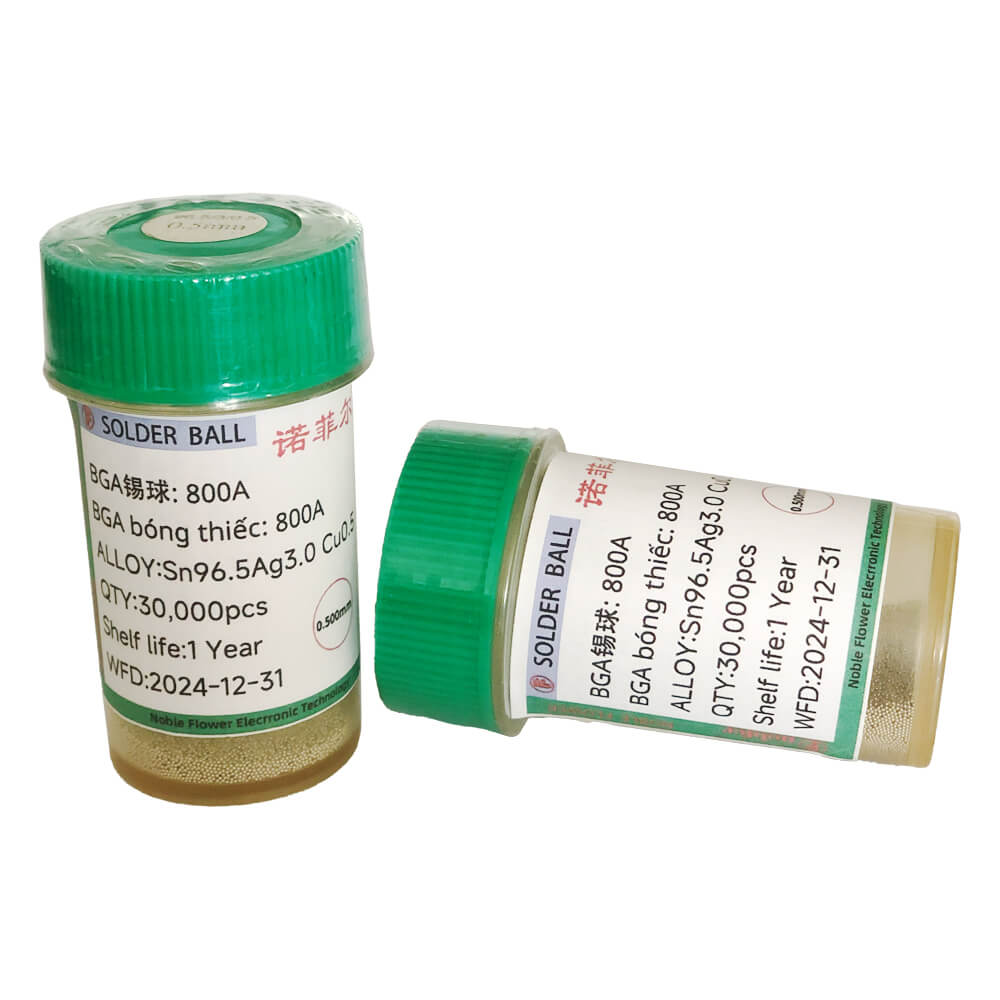

Laser energy focus diameter can be adjusted within the range of 50Мm-200Мm, achieving precise heating of localized areas, with a heat-affected zone (HAZ) ≤0.1mm; Utilizes pulsed laser mode (pulse width adjustable from 0.1ms to 1ms), with peak power density 10⁵-10⁶W/cm², ensuring the solder ball completes the entire process of melting-wetting-solidification within 10ms; Welding experiments on temperature-sensitive components (such as MLCC capacitors, CMOS sensors) show that the component's internal temperature rise can be controlled within 30°C, far lower than the 80°C of traditional hot air soldering. Material Compatibility Design: Supports welding of eutectic solders (e.g., Sn63Pb37, Sn96.5Ag3.5), high-lead alloys (e.g., Sn5Pb95), and lead-free solders (e.g., Sn99Cu0.7, Sn96.5Ag3Cu0.5) without changing core components; For different solder characteristics, 20 sets of process parameter templates are built-in, allowing quick calling and optimization (e.g., laser power for lead-free solder is increased by 15-20% compared to leaded solder); The solder ball feeding system adopts a modular design, with debugging time for changing different diameter solder balls ≤30 minutes, meeting the needs of multi-variety flexible production.

Operational Convenience and Environmental Characteristics of the System

The laser solder jet welding system is designed with full consideration of industrial production needs, forming technical characteristics that balance efficiency and environmental protection: Flexible Production Support: Uses universal clamping equipment (compatible with EROWA, 3R, and other standard fixture systems), with fixture debugging time during product changeover ≤15 minutes; Equipped with an online conveyor mechanical interface (complying with SMEMA standards), enabling seamless connection with front-end printers and back-end inspection equipment, achieving production line automation integration; Supports both robot offline programming and online teaching modes, with new solder joint program creation time ≤10 minutes per point. Green Manufacturing Characteristics: The welding process does not require flux, avoiding the corrosion risk caused by flux residue in traditional processes (insulation resistance ≥10¹²Ω); No volatile organic compound (VOC) emissions, noise level ≤70dB, complying with GB/T 18487.1-2015 environmental standards; Solder ball utilization rate reaches 99.5%, much higher than the 85% of traditional solder paste printing, reducing solder waste by approximately 30kg per device per year.

Industry Application Scenarios and Technical Value of Laser Solder Jet Welding Systems

Laser solder jet welding systems demonstrate irreplaceable application value in multiple electronic manufacturing fields by virtue of their unique technical advantages, especially excelling in precision connection scenarios where traditional welding processes struggle.

High-Density Interconnection Applications in Consumer Electronics

Consumer electronic products such as smartphones and wearable devices are rapidly developing towards "thinness, lightness, and integration," facing dual challenges of miniaturization and high density for internal component welding: Smartphone Motherboard BGA Rework: In the rework of BGA chips (e.g., CPU, RF chips) on 5G smartphone motherboards, the system achieves precise welding of 0.4mm pitch solder joints. Data from a smartphone OEM shows that after adopting laser solder jet welding technology, the BGA rework success rate increased from 75% with traditional hot air soldering to 98%, and the rework time per motherboard was reduced by 40%; Wearable Device Battery Connection: For connecting miniature batteries (size 3mm×5mm) in smartwatches to flexible circuit boards, using 350Мm solder balls achieves reliable welding, with solder joint pull-shear strength reaching 1.5N, meeting the requirement of 10,000 bending tests; Camera Module Welding: In the connection of VCM (voice coil motor) and flexible board in smartphone cameras, laser solder jet welding achieves precise connection of Ф0.3mm pads, with post-weld optical performance deviation of the module ≤0.5%, far lower than the industry standard of 2%.

High-Reliability Welding Requirements in Automotive Electronics

Automotive electronic components need to operate long-term in a wide temperature environment of -40°C to 125°C, placing stringent requirements on the mechanical strength and aging resistance of solder joints: Automotive Radar Module: In the RF front-end components of millimeter-wave radar, laser solder jet welding is used to connect GaN power devices to ceramic substrates. After 1000 temperature cycles (-40°C~125°C), the resistance change rate of the solder joints is ≤5%, far better than the 15% of traditional welding; Autonomous Driving Sensors: In the receiving module of LiDAR, the system achieves welding of SiPM (silicon photomultiplier) arrays with 0.5mm pitch. The dark current fluctuation of the post-weld module is ≤10%, ensuring the stability of detection range; Automotive-Grade Connectors: For waterproof connectors (e.g., IP6K9K rating) in automotive wiring harnesses, using 760Мm solder balls achieves simultaneous welding of multiple pins (≤50pin). The waterproof performance of the solder joints shows no abnormalities after 1000 hours of salt spray testing.

Precision Connection Scenarios in Medical Devices

Medical devices have extremely high requirements for cleanliness and precision control during the welding process. The residue-free characteristic of laser solder jet welding makes it an ideal choice: Implantable Medical Devices: In the circuit modules of cardiac pacemakers, using 400Мm solder balls to weld miniature capacitors (0402 package) to titanium alloy substrates. The post-weld insulation resistance of the device is ≥10¹³Ω, meeting biocompatibility requirements; Diagnostic Equipment Sensors: In the biosensor chips of blood glucose monitors, laser solder jet welding connects the working electrode (diameter 0.1mm) to the lead. The post-weld detection accuracy error of the sensor is ≤0.3mmol/L, meeting medical-grade standards; Medical Instrument Motherboards: In the control motherboards of CT equipment, for BGA-packaged FPGA chips (20mm×20mm), the system achieves overall welding of 0.8mm pitch solder joints. The post-weld motherboard failure rate decreases from 3% with traditional processes to 0.5%.

Special Welding Applications in Aerospace

Aerospace electronic equipment needs to maintain reliable operation in extreme environments (e.g., high vibration, strong radiation), posing special challenges for welding technology: Satellite Communication Modules: In the RF front-end modules of satellites, laser solder jet welding is used to connect microwave RF chips to waveguides. The leakage rate of solder joints in a 10⁻⁵Pa vacuum environment is ≤1×10⁻¹⁰Pa・m³/s; UAV Flight Control Systems: In the flight control motherboards of industrial-grade UAVs, for BGA solder joints (0.5mm pitch) of ARM processors, laser solder jet welding is used for rework. The post-weld system's vibration test (20g acceleration, 10-2000Hz) pass rate reaches 100%; Launch Vehicle Circuits: In the circuit modules of rocket attitude control systems, using high-lead solder balls (Sn5Pb95) to weld high-temperature resistant components. The solder joints can withstand long-term operating temperatures of 250°C, meeting space environment requirements.

Innovative Applications in Flexible Electronics and Emerging Fields

With the development of flexible electronics and wearable technology, traditional rigid welding processes can no longer meet the demands. Laser solder jet welding demonstrates unique advantages: Flexible Displays: In the drive circuit connection of OLED flexible screens, the system uses 350Мm solder balls to achieve welding between COF (Chip on Film) and flexible substrates. The post-weld bending radius can reach 1mm, with no solder joint failure after 100,000 bends; Photovoltaic Components: In the electrode connection of perovskite solar cells, laser solder jet welding achieves low-temperature (≤150°C) welding, avoiding the impact of high temperature on battery performance. The component conversion efficiency retention rate is ≥95%; IoT Sensors: In the connection of antenna and chip in RFID tags, using 400Мm solder balls achieves ultra-fast welding (0.2 seconds per solder joint). The tag's read distance deviation is ≤5%, meeting the needs of large-scale IoT deployment.

Technology Development Trends and Industrial Value Outlook

The continuous innovation of laser solder jet welding systems is driving electronic manufacturing technology towards higher precision, higher efficiency, and greater environmental friendliness. Future technological evolution will focus on three directions: Multi-Solder Ball Simultaneous Welding: Developing array-type laser emission and solder ball jetting systems to achieve simultaneous welding of 10 or more solder joints, increasing production efficiency by 5-10 times; Adaptive Process Optimization: Based on machine learning algorithms, establishing a dynamic mapping model between solder joint quality and process parameters to achieve adaptive welding parameter adjustment for different materials and structures; Micron-Level Ultra-Fine Welding: Through the combination of ultraviolet laser (wavelength 355nm) and nano solder ball (diameter 50-100Мm) technology, breaking through the welding bottleneck of ultra-fine pitches below 0.2mm.

From an industrial value perspective, the maturity and popularization of domestic laser solder jet welding systems not only break the monopoly of foreign brands in the high-end welding equipment field (imported equipment prices are typically 3-5 times that of domestic ones) but also promote the technological upgrade of electronic manufacturing enterprises – it is estimated that adopting this system can reduce the manufacturing cost of electronic components by 15-20% and improve product reliability by over 30%. Under the strategic background of Industry 4.0 and smart manufacturing, this high-precision, high-flexibility welding technology will become a key support for the transformation and upgrading of the electronic information industry, helping China advance from a large electronic manufacturing country to a manufacturing powerhouse.

Безопасность сети 32058300438

Безопасность сети 32058300438