Замечания:1 创始人: Site Editor Publish Time: 2026-01-31 Origin: Веб - сайт

Panoramic analysis of BGA pelleting

technology: method comparison and process optimization

In the manufacturing process of ball grid

array packaging (BGA), the ball planting process is like installing a

"communication tentacle" on the chip, which directly determines the

reliability of the electrical connection between the package and the PCB. This

precision of deploying micron-sized solder balls on a pad array is both a core

part of BGA packaging and a key bottleneck in production yield. With the

evolution of electronic devices to high-density and miniaturization, the BGAsolder ball spacing has been reduced from 1.27mm in the early days to 0.3mm or

even smaller, and the requirements for ball implantation accuracy have reached

±25μm. This paper systematically sorts out the process characteristics of the

four mainstream ball transplanting technologies, deeply analyzes their

technical principles, parameter control points and applicable scenarios, and

provides accurate process selection guidelines for different production needs.

1. BGA ball planting technology basics

The BGA package is electrically

interconnected through a matrix of solder balls at the bottom, and the quality

of the pellets directly affects three key metrics: the mechanical strength of

the solder joints (the shear force requirement of 5kgf/ball of the JEDEC

JESD22-B117A standard must be met), signal transmission integrity (parasitic

inductance is controlled below 5nH), and thermal conductivity (thermal

resistance coefficient ≤1.5°C/W). To understand the underlying logic of ball

planting technology, we need to start from the characteristics of solder balls

and the essence of the process.

1.1 Material characteristics of solder

balls

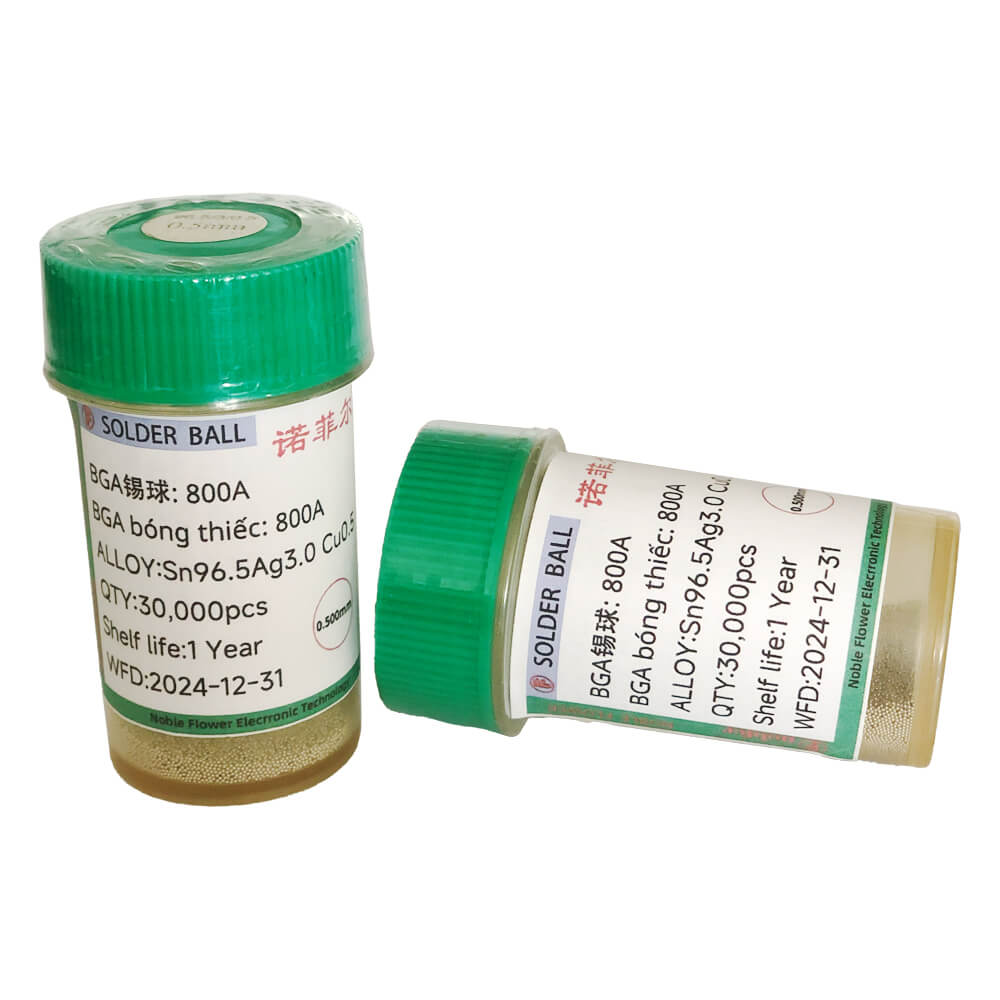

The mainstream BGA solder balls feature

SAC305 lead-free alloy (tin - 3% silver - 0.5% copper), and its key physical

parameters include:

Melting Point: 217°C (34°C higher than

traditional tin-lead alloys), Diameter Tolerance: ±0.02mm (J-STD-006 Class 3

compliant), Sphericity: ≥95% (ensures uniform force during welding), Oxide Thickness:

≤5nm (controlled by vacuum packaging).

These characteristics determine that the

pelleting process must precisely control the temperature profile (peak

245±5°C), flux activity (pH 3.5-4.5), and environmental cleanliness (Class 1000

cleanroom).

1.2 The essence of the ball planting

process

Regardless of the method, BGA ball planting

requires three core tasks:

Positioning accuracy control: The deviation

between the center of the solder ball and the center of the pad should be ≤ 15%

of the ball diameter (e.g., the maximum deviation allowed for a 0.4mm ball

diameter is 0.06mm), and the welding interface is formed: a 3-5μm thick Cu₆Сн.₅ intermetallic compound (IMC) layer is formed through reflow soldering, and the defect rate control is

controlled at 0.1% for fatal defects such as bridging and virtual soldering The

difference between the following different ball transplanting techniques is

essentially the difference in efficiency and accuracy in achieving these three

tasks.

2. In-depth analysis of mainstream ball

planting technology

2.1 Template ball planting method: the king

of efficiency in mass production scenarios

As the preferred solution for mass

production, the core of the formwork pelleting method is to achieve batch

positioning of solder balls through laser-machined stainless steel formwork,

and the whole system complies with IPC-7525 template design specifications.

Technical principle: Using 0.1-0.15mm thick

304 stainless steel template, the opening (diameter = solder ball diameter +

0.075mm) matching the pad array is cut by ultraviolet laser, and the solder

paste is accurately coated by the printing machine, and the automatic filling of

the solder ball is realized by mechanical vibration. The stencil positioning

uses a three-point calibration mechanism with a repeatability of up to ±10μm,

ensuring that each solder ball falls accurately into its intended position.

Detailed explanation of the process

1. Solder Paste Printing Stage: Using a

semi-automatic printing machine such as the Europlacer iineo, the SAC305 solder

paste is evenly applied to the BGA pad at a thickness of 80±5μm. At this stage,

the squeegee pressure (5±0.5N) and printing speed (20mm/s) should be controlled

to ensure that the deviation of solder paste amount ≤ 10%.

2. Template alignment stage: Identify the

positioning marks of the BGA substrate through the CCD vision system, align the

template with the pad array, and control the positioning error within ±25μm.

The gap between the template and the substrate is set to 1/3 of the diameter of

the solder ball (e.g., 0.4mm solder ball corresponds to 0.13mm gap) to prevent

solder ball sticking.

3. Solder ball filling stage: Automatic

ball spreaders such as Parmi SG-200 evenly distribute solder balls on the

surface of the template through a vibrating screen, using negative pressure to

adsorb excess solder balls, and the filling rate can reach more than 99.5%. At

this stage, the vibration frequency (50Hz) and amplitude (0.5mm) should be

controlled to avoid the solder ball bounce misalignment.

4. Reflow soldering stage: Adopt

Ramp-Soak-Spike standard temperature curves: preheating section (150°C/60s),

constant temperature section (180°C/90s), and reflow section (245°C/30s), and

the cooling rate is controlled within 3°C/s to ensure uniform growth of the IMC

layer.

Performance advantages and limitations: Single-hour

production capacity (UPH) of up to 1200 pieces, position repeatability of

±0.01mm, suitable for mass production of templates High manufacturing cost

(about $500 per piece), replacement of product models requires reproduction of

templates, and poor flexibility

2.2 Ball implanter method: balanced

selection for small and medium batches

The ball planter method combines vacuum

adsorption and optical alignment to achieve precise ball planting in medium

batch production, which has unique advantages in multi-variety and small batch

scenarios.

Vacuum system: using scroll vacuum pump, the vacuum level is stabilized at -80kPa~-90kPa, ensuring that small solderballs with a diameter of 0.3mm can also be reliably adsorbed, vision system: equipped with 2μm resolution CCD camera and dual telecentric lenses to realize the synchronous identification of the pad and solder balls, temperature control platform: using PID temperature control heating table, the substrate temperature is stabilized at 35±2°C, Enhanced flux activity

Key process parameters

Поток Selection: ROL0 no-clean flux (solids

< 3%) with a viscosity controlled at 80-120kcp (25°C) to ensure neither

bridging due to excessive fluidity nor affecting solder ball adhesion due to

excessive viscosity

Ball planting pressure: Dynamically adjust

according to the diameter of the solder ball, 0.3mm ball corresponds to

0.5N/ball, 0.5mm ball corresponds to 1.2N/ball, too much pressure will cause

damage to the pad, too small will affect the bonding strength

Environmental control: Reflow after ball

planting in a nitrogen protection atmosphere, and the oxygen content is

controlled below 500ppm to reduce solder ball oxidation

Yield improvement techniques

Bake the BGA substrate at 150°C/2 hours

before ball planting, control the moisture content below 0.02%, avoid bubbles

during reflux, and carry out vacuum adsorption calibration every 500 pieces

produced to ensure that the adsorption deviation does not exceed ±5%, and adopt

a step-by-step ball planting strategy: first plant the four-corner positioning

ball, confirm the position accuracy and then plant the ball in batches, which

can control the positioning error to ± Within 0.05mm

2.3 Solder paste printing ball planting

method: a flexible solution for R&D scenarios

The solder paste printing ball planting

method directly prints the "solder ball shape" solder paste stack

through a specially designed template, and forms a solder ball after reflow,

which is especially suitable for rapid verification in the R&D stage.

Stepped template design: The template

opening adopts a stepped structure with a wide top and a narrow bottom (upper

notch + 0.1mm, lower notch - 0.05mm), using the surface tension of the solder

paste to form an almost spherical solder joint, reducing the subsequent shaping

process, and optimizing the characteristics of the solder paste: Type 4 tin

powder (particle size 20-38μm) is selected, the mixing ratio (metal content) is

controlled at 89±1%, and the thixotropic index is > 0.6, ensure good shape

retention after printing, process window control: squeegee angle 60°±5°,

printing speed 10-20mm/s, release speed 0.5-1mm/s, the combination of these

parameters can minimize the solder paste tailing phenomenon

Common defect solutions

|

Defect type |

Causes |

Solution |

|

The ball diameter is uneven |

Solder paste viscosity fluctuations |

Adjust the thixotropic ratio to stabilize

the viscosity at 180-220kcp |

|

The bridge is connected to a short

circuit |

The spacing between the template openings

is too small |

Increase the opening spacing to more than

1.5 times the ball diameter |

|

The solder ball collapsed |

The reflux temperature is too high |

Reduce peak temperature to 240±5°C |

|

The hollow exceeds the standard |

The flux is incompletely volatilized |

Extend the constant temperature period to

120s |

2.4 Manual ball planting method: emergency

choice for maintenance scenarios

The manual ball planting method relies on

manual operation to complete the ball planting, and is mainly used for

prototype verification (<10pcs) or maintenance occasions when equipment is

in short supply, and its quality control is the most difficult.

Operating specifications

ESD protection: must be equipped with an

ion fan (balanced voltage <±35V), an anti-static bracelet (impedance

10⁶-10⁹Ω) and an anti-static workbench to avoid static breakdown of the chip, use

an optical microscope of more than 20 times to assist positioning, and use a

tungsten steel probe (0.1mm diameter) for solder ball adjustment to avoid

scratching the padOperators need to pass IPC-7711/7721 CIS certification, be

proficient in solder paste coating (thickness 50-80μm) and heat gun use

(temperature 250±10°C), manual ball implantation usually has a fatal defect

rate of 10-15%, and the risk should be reduced by the following measures: Use

the "dispense first, then plant the ball" process: apply a small

amount of flux (0.2mm diameter) to the center of the pad and then place thesolder ball to improve positioning accuracy Heating: The heat gun is preheated

at 150°C for 30s, then heated to 245°C for 60s to reduce thermal shock, 100%

X-ray inspection: Use equipment such as the Dage XD7600 to check the internal

voidity rate of the solder joint, ensuring a ≤ of 25%

3. Comparison of technical parameters and

selection guidelines

3.1 Comparison of core parameters of the

four types of technology

|

Evaluation indicators |

Template ball planting method |

Ball planter method |

Solder paste printing method |

Hand ball planting method |

|

Capital Investment (USD) |

50,000+ |

15,000 |

30,000 |

<1,000 |

|

Single ball planting time (s) |

0.01 |

0.5 |

0.05 |

5-10 |

|

Positioning accuracy (mm) |

±0.01 |

±0.05 |

±0.03 |

±0.15 |

|

Yield (%) |

99.8 |

98.5 |

97.2 |

85.6 |

|

Applicable batches |

>10,000pcs |

1,000-5,000pcs |

100-1,000pcs |

<100pcs |

3.2 Scenario-based selection suggestions

Large-scale mass production scenario

Template ball implantation + AOI inspection

system, equipped with automatic optical inspection equipment such as Omron

VT-S500, to achieve a defect recognition rate of 99.99%, with a dual-track

printing machine configuration, to achieve a production capacity of 1500 pieces

per hour, key control points: stencil cleanliness (wipe every hour), solder

paste viscosity (every 4). Detect once an hour).

Multi-variety small and medium-sized batch

scenarios

Ball planter method + quick change system, equipped

with more than 3 sets of positioning fixtures, to achieve 5-minute quick change

of different BGA models, using offline programming system, complete the ball

planting program in advance, reduce downtime, key control points: vacuum

adsorption calibration, optical system focal length adjustment

R&D verification scenario

Solder paste printing method + flexible

template, using magnetically fixed flexible stencil, can quickly modify the

opening design (suitable for parameter iteration), with a small reflow oven

(e.g. ERSA HOTFLOW 2/20) to achieve small batch trial production, key control

points: solder paste refrigeration conditions (5-10°C, shelf life 6 months),

Warm-up time (≥4 hours).

Maintenance emergency scenarios

Recommended scheme: manual ball planting

method + X-ray re-inspection, making simple positioning fixtures (accuracy

±0.1mm), improving the efficiency of manual ball planting, using local heating

head (diameter 3mm) for selective reflow to avoid damage to peripheral

components, key control points: operator qualifications, effectiveness of

electrostatic protection measures

4. Process optimization and development

trend

Common process optimization direction

Regardless of the pelleting method, the

following optimizations can significantly improve quality: Pad pretreatment:

Plasma cleaning (500W, 60s) to remove the oxide layer to achieve a pad contact

angle of < 30°, Flux management: Precise control of the solder dose

(0.005-0.01μL/pad) using a syringe dispensing valve to avoid overdose

bridgingReflow curve optimization: Adjust the temperature ramp-up rate (2°C/s ≤

large devices) according to the BGA size to reduce thermal stress

Technology development trends: Intelligent

ball planting system: integrating machine vision and AI algorithms to realize

online identification of solder ball defects and adaptive adjustment of

parameters (prediction accuracy > 95%), micro-pitch ball implantation

technology: development of nanoscale positioning system (accuracy ±5μm) and

low-spatter solder paste for pitches below 0.3mmLead-free advancement: Study

Sn-Bi-In alloys with low melting points (melting point 170-180°C) to reduce

thermal damage to the substrate

The choice of BGA pelleting technology is

essentially a balance between precision, efficiency and cost. With the

development of electronic packaging towards high density and high reliability,

the pelleting process is shifting from "experience-led" to

"data-driven", and the control goal of ppm-level defect rate is

achieved through the digital management of process parameters and the quality

traceability of the whole process. In the future, with the development of

heterogeneous integration technology, the ball planting process will be deeply

integrated with 3D packaging, hybrid bonding and other technologies, and become

the core supporting process of advanced packaging manufacturing.

Безопасность сети 32058300438

Безопасность сети 32058300438