Замечания:1 创始人: Site Editor Publish Time: 2026-02-01 Origin: Веб - сайт

Laser ball implantation technology:

high-precision bump manufacturing solution for BGA chip packaging

In the wave of semiconductor packaging

technology moving towards high density and miniaturization, ball grid array

(BGA) packaging has become the core packaging solution for advanced process

chips below 3nm due to its excellent I/O density and electrical performance.

According to the latest report from SEMI, the global BGA packaging market will

exceed $38 billion in 2023, with high-end products using advanced pelleting

processes accounting for 62%. Laser ball implantation technology, a

high-precision manufacturing process that has rapidly emerged in recent years,

is reshaping the technological landscape of BGA bump manufacturing with a

positioning accuracy of ±15μm and a yield performance of 99.9%. This article

will systematically analyze the working principle, process characteristics and

application boundaries of this technology, and provide a comprehensive

technical reference for advanced packaging production lines.

1. Technical background and industry

needs

The continuous miniaturization of

integrated circuit chips is driving the simultaneous innovation of packaging

technology. With over 60 billion transistors integrated into today's

state-of-the-art 3nm process chips, this ultra-high integration imposes triple

core requirements for I/O interfaces: finer pitch (≤0.3mm), higher coplanarity

(≤25μm), and more reliable electrical connections (parasitic inductance

<0.5nH). Traditional pelleting processes are gradually showing bottlenecks

in responding to these demands: the minimum pitch of the stencil pelleting

method is limited by the stencil processing accuracy (≥0.4mm), and the solder

paste printing method faces the problem of insufficient ball diameter

consistency (deviation > 10%).

The emergence of laser ball implantation

technology just fills this technical gap. With the precise energy control of

the 1070nm fiber laser, this technology enables stable manufacturing of

50-300μm diameter solder balls, especially for micro devices under the 0201

package size. In high-end applications such as 5G base station RF chips and AI

training chips, laser ball implantation has become a key process to ensure

signal integrity - test data shows that BGA packages with this technology have

23% lower signal loss in the 10GHz band than traditional processes.

2. Principle and system composition of

laser ball implantation technology

The core of laser ball implantation

technology is to use the directional energy deposition characteristics of

lasers to form spherical bumps on the surface of the pads, and its process

essence is to achieve three-dimensional structural shaping by precisely

controlling the melt-solidification process of the material.

2.1 Core working principle

The entire process can be divided into four

stages:

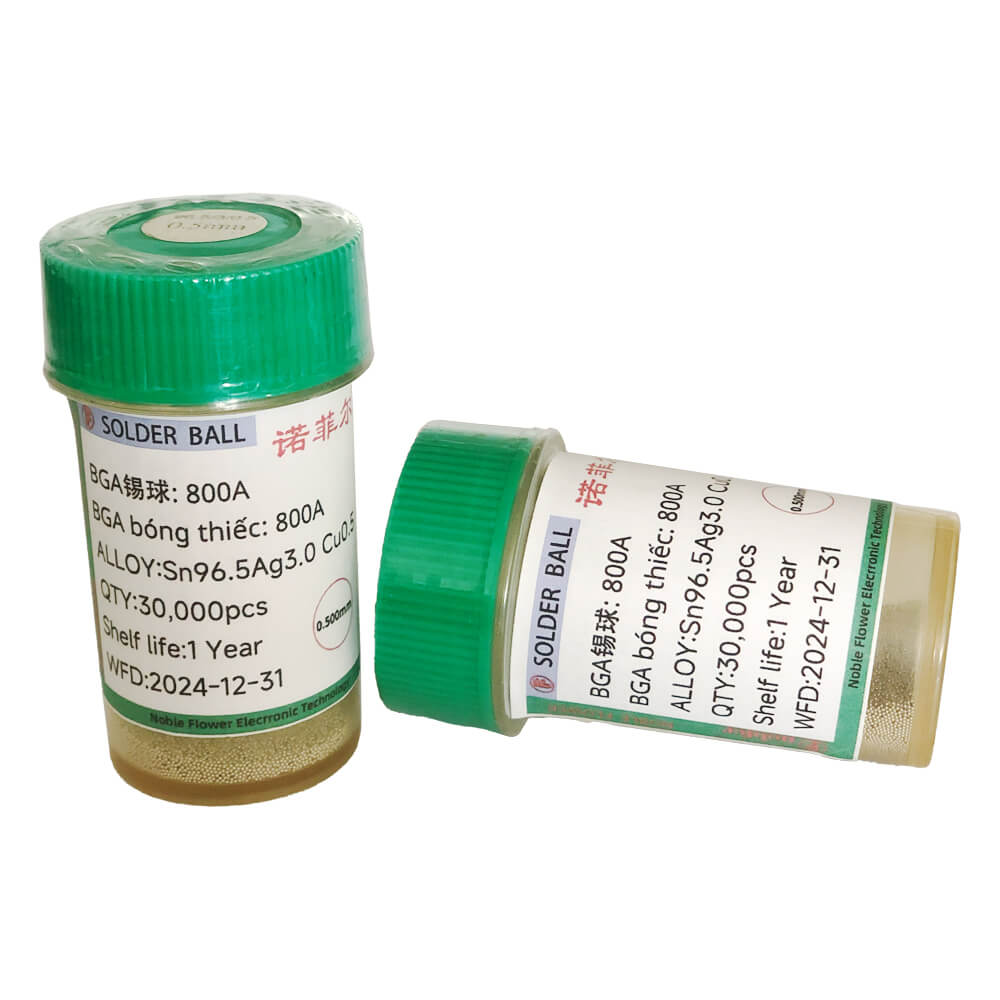

1. Material preparation stage: Sn-3.5Ag-0.7Cu alloy welding wire (melting point 217°C) is used as

raw material, and accurately conveyed to the laser action area at a speed of

5-10mm/s through the wire feeding mechanism. The alloy composition is certified

by JEDEC J-STD-006 and offers excellent oxidation resistance and mechanical

strength.

2. Laser melting stage: A fiber laser with a wavelength of 1070nm (power 50-150W) is

focused into a spot with a diameter of 50-100μm through a galvanometer system,

instantly melting the end of the welding wire into droplets in a nitrogen

protection atmosphere (oxygen content < 50ppm). The laser pulse width is

precisely controlled from 10-50ms, ensuring the formation of volume-stable

molten metal balls (mass deviation < 3%).

3. Positioning transfer stage: The molten droplet maintains a spherical shape under the action of

surface tension, and the high-precision motion platform (positioning accuracy

±5μm) drives the workpiece table to move, and the droplet is accurately

transferred to 0.1-0.3mm above the pad of the preset flux. The flux is

formulated in a no-clean formulation of ROL0 grade (< 2% solids) and is

applied through a needle dispensing valve (50-150μm diameter).

4. Solidification and molding stage: After the droplet comes into contact with the pad, it is well

wetted under the action of flux, and at the same time, it solidifies quickly

through inert gas cooling (rate 5-10°C/ms), forming bumps that combine with pad

metallurgy. During solidification, a 3-5 μm thick layer of Cu₆Sn₅

intermetallic compounds (IMCs) naturally forms, which

is a critical structure that ensures the long-term reliability of solder

joints.

2.2 Key components of the system

A complete laser ball implantation system

consists of five core modules:

Laser Subsystem: Adopts Q-switched fiber laser, supports continuously adjustable

power (10-200W), beam quality M²<1.2, ensures uniform energy distribution

(spot energy deviation < 5%).

Motion control subsystem: XYZ three-axis linear motor platform, repeatable positioning

accuracy of ±3μm, maximum motion speed 500mm/s, meeting the efficiency needs of

mass production.

Visual positioning subsystem: dual CCD camera configuration (up view + down view) with a

resolution of 1μm/pixel, with deep learning image algorithms, real-time

alignment of the pad with the laser focus (response time < 10ms).

Wire feeding mechanism: Roller type wire feeding driven by servo motor, with a minimum

wire feeding volume of 0.01mm, support welding wire specifications with a

diameter of 0.1-0.5mm, and a wire feeding accuracy of ±0.005mm.

Environmental Control Module: Includes nitrogen purification system (flow rate 10-30L/min),

thermostatic unit (operating temperature 25±1°C), and dust cover (ISO Class 5

cleanliness) to provide a stable microenvironment for the process.

3. Optimization of process parameters

and quality control

The quality of laser ball implantation

depends on the collaborative control of multiple parameters, and a scientific

parameter optimization system needs to be established to achieve high-precision

and high-consistency bump manufacturing.

3.1 Influence law of key parameters

500 sets of experiments conducted through

the Design of Experiment (DOE) method showed that the following parameters had

a significant impact on bump quality:

|

parameter items |

Value range |

Impact on quality |

Optimize target values |

|

Laser power |

50-150W |

Too low will cause incomplete melting,

and too high will cause spatter |

80-100W |

|

Pulse width |

10-50ms |

Too short forms small balls, and too long

causes the pad to overheat |

20-30ms |

|

Wire feeding speed |

5-10mm/s |

It directly determines the size of the

ball diameter, and the fluctuation of speed affects the consistency |

7±0.2mm/s |

|

The amount of defocus |

-0.1-+0.1mm |

Affects the energy density distribution

of the spot |

0±0.02mm |

|

Cooling rate |

5-10℃/ms |

Internal stress is generated too quickly,

and oxidation is caused by too slow |

7-8℃/ms |

The optimized process parameters can be achieved: ball diameter deviation of ≤±3%, solder ball height consistency of ≤ 5 μm, and alignment error with pad center ≤ 10 μm, fully meeting the requirements of the IPC-7095 standard for Tier 1 packaging.

3.2 Typical defect solutions

Possible defects and countermeasures during

laser ball implantation are as follows:

Bump deviation: mainly caused by visual positioning error or insufficient platform

motion accuracy. The solution includes: visual calibration every hour

(deviation compensation < 2μm) and regular testing of the positioning

accuracy of the linear motor (once a month).

Uneven ball diameter: usually caused by fluctuations in wire feed speed or instability

in laser energy. The standard deviation of the ball diameter can be controlled

to less than 2 μm by using a closed-loop controlled wire feed system (feedback

frequency 1 kHz) and a laser power monitoring module (sampling rate 10 kHz).

Surface oxidation: It is manifested as a gray area on the surface of the bump, caused

by insufficient purity of the shielding gas. It is necessary to ensure that the

nitrogen purity ≥ 99.999%, and is monitored in real time by an online oxygen

content monitor (accuracy of 1ppm), and automatically alarms when the oxygen

content exceeds 30ppm.

Pad damage:

Excessive laser energy can cause the pad copper layer to melt. Thermal damage

can be avoided by setting the upper limit of the laser power (which dynamically

adjusts to the pad size) and introducing infrared temperature monitoring

(response time < 1ms).

4. Technical advantages and application

scenarios

Compared with traditional ball

transplanting processes, laser ball implantation technology shows significant

advantages in multiple dimensions, making it an ideal choice for specific

application scenarios.

4.1 Core technical advantages

1. Precision breakthrough: The positioning accuracy reaches ±15μm (3σ), which is 60% higher

than the template ball planting method, which can meet the manufacturing needs

of micro-pitch BGA below 0.3mm. In the production of a 5G RF module, the

coplanarity of the weld ball was increased from 45 μm to 20 μm after using this

technology, greatly reducing the risk of false soldering in subsequent

assembly.

2. Material Savings: By precisely controlling the amount of melt, the material

utilization rate reaches more than 95%, reducing solder waste by 40% compared

to the solder paste printing method (60-70%). Based on the annual output of 100

million BGAs, the solder cost savings are approximately $2.8 million.

3. Environmental Benefits: No need to use solvent-based fluxes, reducing organic volatile

compound (VOC) emissions by more than 60% compared to traditional processes,

complying with the requirements of RoHS 2.0 and China's "Pollutant

Emission Standards for the Electronics Industry".

4. Flexible production: There is no need to change the template when changing product

models, and rapid type change (< 10 minutes) can be achieved by calling

different process parameter files, which is especially suitable for

multi-variety and small-batch production modes. When a semiconductor packaging

plant introduced the technology, product changeover time was reduced from 2

hours to 8 minutes, and equipment utilization was increased by 35%.

4.2 Applicable scenarios and technical

boundaries

The best application scenarios for laser

ball implantation technology include:

High-end chip packaging: such as CPUs, GPUs, and other devices with high-density I/O, with

a solder ball diameter of 100-300μm and a pitch of 0.3-0.8mm. Miniature

Sensor Packages: Micro BGAs in medical implantable devices with solder ball

diameters as small as 50μm. High-reliability requirements: aerospace

electronics, automotive safety chips, etc., products that need to pass AEC-Q100

Grade 0 certification.

The current application boundary of this

technology is that when the solder ball diameter exceeds 500 μm, the production

efficiency (about 3000 points/hour) is lower than that of the template ball

implantation method (10000 points/hour), so it is more suitable for the

manufacture of small and medium-sized weld balls.

5. Comparative analysis with other ball

planting techniques

In order to more clearly show the

positioning of laser ball planting technology, we compare it with the

mainstream ball planting process in multiple dimensions:

|

Evaluation indicators |

Laser ball implantation method |

Template ball planting method |

Solder paste printing method |

Electroplating method |

|

Minimum Sphere Diameter (μm) |

50 |

200 |

150 |

50 |

|

Minimum pitch (μm) |

300 |

400 |

350 |

100 |

|

Positioning accuracy (μm) |

±15 |

±25 |

±30 |

±5 |

|

Ball diameter deviation (%) |

<3 |

<5 |

<10 |

<2 |

|

Capital Investment (USD) |

350,000 |

50,000 |

30,000 |

500,000 |

|

Cost per Unit (USD) |

0.003-0.005 |

0.001-0.002 |

0.002-0.003 |

0.01-0.02 |

|

Capacity (dots / hour) |

3,000-5,000 |

10,000-15,000 |

8,000-10,000 |

1,000-2,000 |

|

Suitable for batches |

Medium Volume (1K-10K) |

High Volume (>10k) |

Small to medium batch (100-5k) |

Small Batch (<1k) |

It can be seen from the comparison that

laser ball implantation has achieved a good balance between precision and cost,

especially in scenarios that require both precision and flexibility. Although

the electroplating method has the highest precision, the high equipment

investment and operating costs make it mainly used in special occasions with

ultra-fine pitch (≤ 100μm).

6. Technology development trends and

practical suggestions

Laser ball implantation technology is

rapidly evolving in the direction of higher precision and efficiency, while

making continuous breakthroughs in material adaptation and system integration.

6.1 Future technological breakthroughs

Multi-beam parallel processing: Development of 4-8 laser parallel systems is expected to increase

capacity to 20,000 points/hour, close to the efficiency level of the template

ball planting method.

Real-time quality monitoring: High-speed visual inspection module with integrated machine

learning algorithms enables online identification of bump defects (accuracy

> 99.5%) and adaptive adjustment of process parameters.

Low-temperature pelleting process: Research Sn-Bi-In alloys with low melting point (melting point

170-180°C), combined with energy-modulated laser technology, to achieve

pelleting processing of temperature-sensitive substrates (such as flexible PI

materials).

3D Package Adaptation: Developed tilt angle ball planting function (±45°) to meet the

needs of side interconnection in 3D stacked packages, and has achieved stable

machining with a 15° tilt angle in the laboratory stage.

6.2 Engineering application suggestions

For enterprises planning to introduce laser

ball implantation technology, the following implementation paths are

recommended:

1. Equipment Selection: Prioritize fully automated systems with integrated 3D AOI

detection capabilities, ensuring closed-loop control from ball planting to

inspection. The laser power stability of the device (fluctuation < 2%) and

the accuracy of the motion platform were the key indicators to be investigated.

2. Process verification: Conduct temperature and humidity sensitivity level testing in

accordance with the JEDEC J-STD-020D standard, with special attention to the

reliability performance of 1000 hours in an 85°C/85% RH environment to ensure

that the growth thickness of the IMC layer is controlled at 5-8μm.

3. Personnel training: Operation engineers need to be familiar with laser safety

specifications (in accordance with IEC 60825-1) and process parameter debugging

methods, and it is recommended to pass IPC-A-610 certification training.

4. Cost control: By optimizing laser pulse parameters (e.g., pulse shaping

technology) to reduce unit energy consumption, while increasing wire

utilization (target > 97%), the cost per piece can be reduced by another

15-20%.

The maturity and popularization of laser

ball implantation technology are driving the transformation of BGA packaging

from "large-scale production" to "precision manufacturing".

In the semiconductor industry's pursuit of "More than Moore", this

technology will be deeply integrated with advanced concepts such as

heterogeneous integration and chiplets, providing key process support for

building electronic systems with higher performance and higher reliability.

With the breakthrough of localized equipment (such as the latest laser ball

planting machine of China Micro Company has achieved ±20μm accuracy), it is

expected that the application cost of this technology will be reduced by more

than 40% in the next 3-5 years, further accelerating its large-scale application

in consumer electronics, automotive electronics and other fields.

Безопасность сети 32058300438

Безопасность сети 32058300438