MSDS (Material Safety Data Sheet), that is, the Safety Data Sheet of

Chemicals, can also be translated as Safety Data Sheets for Chemicals or Safety

Data Sheets for Chemicals. In European countries, MSDS is also known as SDS,

which is a document used by chemical manufacturers and importers to explain the

physical and chemical properties of chemicals (such as PH value, flash point,

flammability, reactivity, etc.) and possible harm to the health of users (such

as carcinogenicity, teratogenicity, etc.), containing a total of 16 contents.

1.Chemical

Product and Company Identification: It mainly indicates the name of the

chemical, the name of the manufacturer, the address, zip code, telephone

number, emergency telephone, fax and email address.

2.Information

on Hazardous Ingredients: Indicates whether the chemical is pure or a mixture,

including all hazardous substances containing more than 1% and carcinogens

exceeding 0.1%. If it is a pure chemical, the chemical name or trade name and

generic name should be given; In the case of mixtures, the concentration or

concentration range of the hazardous components should be given. Whether it is

a pure chemical or a mixture, if it contains a hazardous component, the

Chemical Abstracts Index Registry Number (CAS number) should be given.

3.Hazard

identification: Summarize the most important hazards of the chemical and its

impact on health, mainly covering hazard categories, invasion routes, health

hazards, environmental hazards, fire and explosion hazards and other

information.

4.First Aid

Measures: Self-help or mutual rescue methods (e.g., inhalation, ingestion, eye

contact, skin-to-skin treatment) in the event of an accidental injury.

5.Fire

Fighting Measures: It mainly displays the physical and chemical special hazards

of chemicals, suitable fire extinguishing media, unsuitable fire extinguishing

media, and personal protection of firefighters, including hazard

characteristics, fire extinguishing media and methods, fire extinguishing

precautions, etc.

6.意外泄露处置措施(Accidental

Release Measures):清理小型和大型泄漏的程序以及化学物质泄漏周围的具体规定。

7.Handling and

Storage: Provides information on the safe storage and safe use of materials.

8.Exposure

Control/Personal Protection: Protective methods and means used to protect

workers from chemical hazards in the process of producing, handling, handling

and using chemicals, including gloves, clothing, eye protection, and

respiratory protection.

9.Physical and

Chemical Properties: It mainly describes the appearance and physical and

chemical properties of chemicals, including appearance and properties, pH

value, boiling point, melting point, relative density (water = 1), relative

vapor density (air = 1), saturation vapor pressure, heat of combustion,

critical temperature, critical pressure, octanol/water partition coefficient,

flash point, ignition temperature, explosion limit, solubility, main uses and

some other special physical and chemical properties.

10.Stability

and Reactivity: Indicates stable substances, causes of instability and

incompatibility, including stability, prohibited substances, conditions under

which contact should be avoided, polymerization hazards, and decomposition

products.

11.Toxicology

Information: Provides toxicological information of chemicals, including acute

toxicity (LD50, LD50), irritation, sensitization, subacute and chronic

toxicity, mutagenicity, teratogenicity, carcinogenicity, etc.

12.Ecological

Information: It mainly states the environmental and ecological effects,

behaviors and outcomes of chemicals, including biological effects (such as

LD50, LD50), biodegradability, bioaccumulation, environmental transport and

other harmful environmental impacts.

13.Disposal

Considerations: refers to the safe disposal methods of chemical-contaminated

packaging and chemicals with no use value, including disposal methods and

precautions.

14.Transportation

Information: Mainly domestic and international chemical packaging,

transportation requirements and transportation regulations classification and

numbering, including dangerous goods number, packaging category, packaging

mark, packaging method, UN number and transportation precautions.

5.Regulatory

Information: Mainly legal provisions and standards for chemical management, as

well as CITES related EPA and OSHA regulations.

16.Other

Information: It mainly provides other information that is important to

security, such as references, time of filling in the form, department of

filling in the form, data review unit, etc.

In general, MSDS is used to determine

whether the goods are suitable for sea transportation and what appropriate mode

of transportation is used to ensure transportation safety. When booking a

specific cargo for export, the carrier (shipping company) will require an MSDS,

and all personnel who come into contact with or may come into contact with the

cargo (including loading and unloading personnel, depot/warehouse personnel,

etc.) will need an MSDS. Operators must follow the guidelines and instructions

of MSDS for correct operation and disposal, especially in emergencies such as

package damage and leakage, it is difficult to understand the situation without

MSDS, which will delay rescue, and blind action will lead to serious

consequences.

The 16 contents of the MSDS issued by

authoritative institutions are very accurate, for example, the Shanghai

Institute of Chemical Industry can issue them. But now basically the

manufacturer compiles the MSDS by itself, and the accuracy is not high, so many

times it is necessary to refer to the identification certificate to judge

whether it is ordinary goods or dangerous goods. In the actual trade and

transportation of chemical products, the accuracy of MSDS is extremely

critical. It is very common for manufacturers to compile their own MSDS

inaccurately, which makes there are many hidden dangers when judging the nature

of the goods. Since an inaccurate MSDS may not accurately reflect the

characteristics of chemicals, it may lead to misjudgment as to whether the

goods are suitable for sea transportation and what mode of transportation to

use.

When booking cargo, if the carrier is

acting on an inaccurate MSDS, it may transport the cargo that should have been

handled in accordance with the requirements for the transport of dangerous

goods as general cargo, or vice versa. Not only can this be a violation of

transport regulations, but it also poses a significant risk to transport

safety. For example, if an accident occurs during transportation, an inaccurate

MSDS cannot provide accurate information to rescuers, such as when a chemical

is leaked, it is difficult for rescuers to take effective response measures if

it is not clear about its hazard category and suitable fire extinguishing

medium.

Inaccurate MSDS can also prevent operators

from operating correctly during handling, disposal, and storage. For example,

for some chemicals that require special storage conditions, if the MSDS does

not accurately state, it may lead to improper storage, which can lead to

chemical reactions and safety accidents. When it comes to exposure control and

personal protection, the wrong MSDS can lead workers to use inappropriate

protective gear that prevents them from effectively protecting themselves from

chemical hazards.

For the measure of judging whether ordinary

goods or dangerous goods are made by referring to the appraisal certificate,

although it can make up for the inaccuracy of the manufacturer's self-compiled

MSDS to a certain extent, there are also some limitations. On the one hand,

obtaining an appraisal certificate can require additional time and cost; On the

other hand, there may be differences in standards and testing methods between

different accreditation bodies, which may also lead to inconsistencies in judgment

results.

To sum up, MSDS plays an indispensable role

in the production, transportation, storage and emergency treatment of chemical

products, but the current situation of inaccurate MSDS compiled by

manufacturers has seriously affected its function, and measures need to be

taken to improve the accuracy of MSDS to ensure the safety and orderly conduct

of related activities in the chemical industry.

In the actual trade and transportation of

chemical products, the accuracy of the MSDS is crucial. It is not uncommon for

manufacturers to compile their own MSDS inaccurately, which makes there are

many hidden dangers when judging the nature of goods. Since an inaccurate MSDS

may not accurately reflect the characteristics of chemicals, it may lead to

misjudgment as to whether the goods are suitable for sea transportation and

what mode of transportation to use.

When booking cargo, if the carrier relies

on an inaccurate MSDS, it may transport the cargo as general cargo that should

have been handled in accordance with the requirements for the transport of

dangerous goods, or vice versa. Not only can this be a violation of transport

regulations, but it also poses a significant risk to transport safety. For

example, if an accident occurs during transportation, an inaccurate MSDS cannot

provide accurate information to rescuers, such as when a chemical is leaked, it

is difficult for rescuers to take effective countermeasures if it is not clear

about its hazard category and suitable fire extinguishing medium.

In the handling and storage process,

inaccurate MSDS can also prevent operators from operating correctly. For

example, for some chemicals that require special storage conditions, if the

MSDS is not accurately stated, it may lead to improper storage, which can lead

to chemical reactions and safety accidents. When it comes to exposure control

and personal protection, the wrong MSDS can lead workers to use inappropriate

protective equipment that prevents them from effectively protecting themselves

from chemical hazards.

For the measure of judging whether general

goods or dangerous goods are based on the appraisal certificate, although it

can make up for the inaccuracy of the manufacturer's self-compiled MSDS to a

certain extent, there are also some limitations. On the one hand, the

acquisition of an appraisal report may require additional time and cost; On the

other hand, there may be differences in standards and testing methods between

different accreditation bodies, which may also lead to inconsistencies in

judgment results.

To sum up, MSDS plays an indispensable role

in the production, transportation, storage and emergency treatment of chemical

products, but the current situation of inaccurate MSDS compiled by

manufacturers has seriously affected its function, and measures need to be

taken to improve the accuracy of MSDS to ensure the safety and orderly conduct

of related activities in the chemical industry.

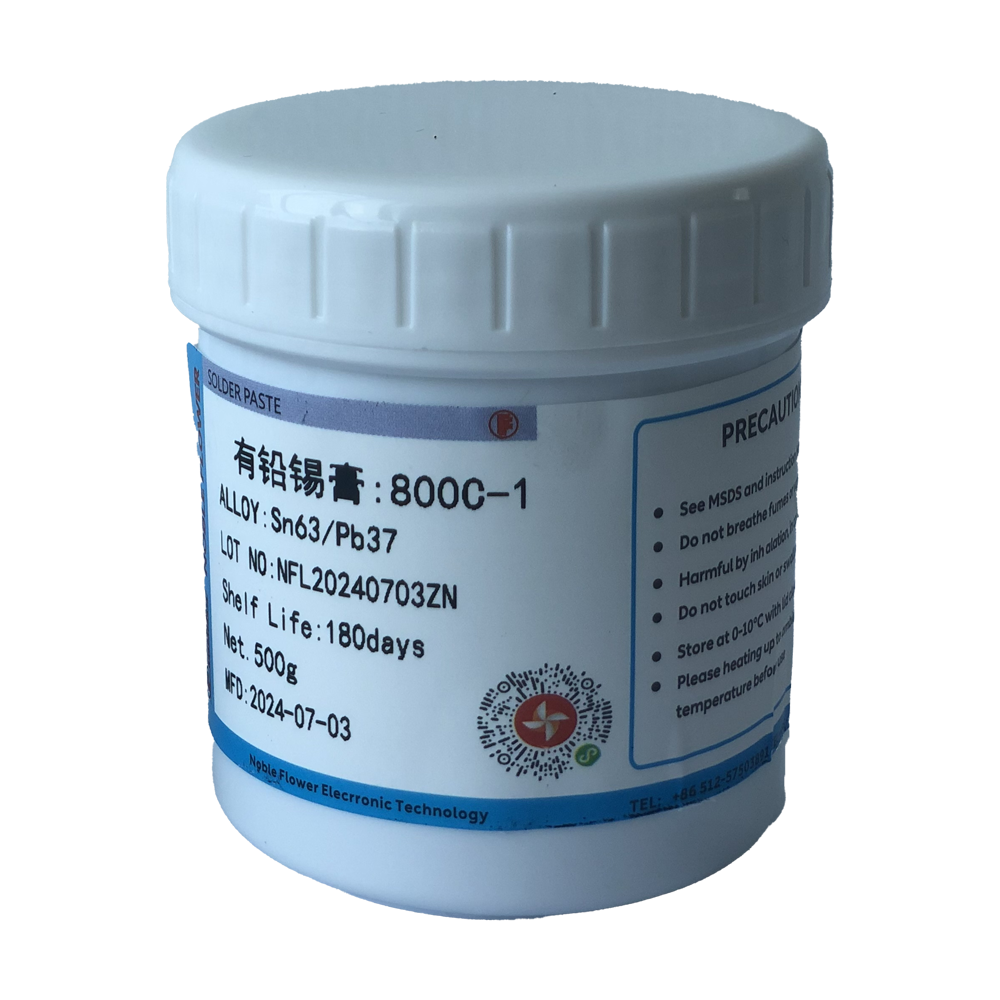

Friends engaged in SMT SMD processing should be no stranger to solder paste. When purchasing solder paste, they are often asked to carefully select the type according to the actual needs and test the samples with Nofel solder manufacturers. This is a very important material. So, what role does such an important material play? Suzhou Neufeld next for your interpretation:

In the 1970s, surface mount technology just began to rise, also known as SMT. this is a printed circuit board pads printed and coated with solder paste technology, in the coated solder paste pads accurately paste the surface of the electronic components, and according to a specific reflow temperature profile to heat the circuit board, so that the solder paste melted. After its alloy composition is cooled and solidified, a solder joint is formed between the component and the printed circuit board to achieve a soldered electronic component connection.

Solder paste is a new type of soldering material that came into being along with the emergence of SMT technology. It is a kind of solder used to connect the electrode of the parts with the pad of the circuit board, and is mainly used in the SMT industry for the soldering of electronic components such as capacitors, resistors and ICs on the surface of the PCB. Solder paste at room temperature also has a certain degree of viscosity, can temporarily stick electronic components in the established position fixed, in the welding temperature, with the solvent and part of the additives volatilisation, the solder paste first melted to fix the pins and soldering, to be cooled down after the electronic components and printed circuit pads welded together to form a stable connection.

Solder paste is a complex system, is a mixture of solder powder, flux and other metal additives into the paste, and change its composition to meet the soldering needs of different products. Therefore, the components that make up a solder paste all have different roles.

The role of solder paste is mainly divided into these modules, the first is the role of the alloy powder, is to complete the mechanical and electrical connection between the electronic components and the circuit board.

Secondly, there is the flux: it is the substance of the tin powder particles, which provides the right rheology and humidity, facilitates the transfer of heat to the soldering area, reduces the surface tension of the solder, and prevents the re-oxidation of the solder and the soldering surface during soldering. Among them, the role of the different components are as follows:

1, the solvent (Solvent): The component is the solvent of the solder component, in the mixing process of the solder paste plays a role in regulating the uniformity of the life of the solder paste has a certain impact;

2, the resin (Resins): the component mainly play an increase in the adhesion of solder paste, but also to protect and prevent the role of solder PCB oxidation again after welding; the component plays a very important role in the parts fixed.

3, the activator (Activation): This component mainly plays the role of removing the PCB copper film pad surface layer and parts of the oxidation of the soldered parts, and at the same time has the effect of reducing the surface tension of tin, lead;

4, thixotropic agent (Thixotropic): the component is mainly to regulate the viscosity of the solder paste and printing performance, to play a role in the printing to prevent the phenomenon of tail dragging, adhesion and so on;

As an 18-year veteran solder paste manufacturer, Nofil Electronic Technology is always committed to the research and development, production and sales of solder paste. Our products are of stable quality, no continuous tin, no false soldering, no cracks; no tin bead residue, bright and full solder joints, solid welding, strong conductivity. If there is a need to use, you can contact our technology, free of charge to provide solutions to solve your problems!

Translated with www.DeepL.com/Translator (free version)

Some special types of solder paste are prone to drying out, and general solder paste suppliers are equipped with special solvents - thinner. However, for some brands of solder paste, there is no major quality problem itself, so they cannot provide solvents for you to add. The next step is for Suzhou Noble Flower solder paste manufacturers to say a few words:

When the solder paste is dry, never dilute it with water.

Tin paste is absolutely prohibited to mix with water, if a small amount of tin paste for occasional use, can be mixed with a small amount of alcohol, stirred well after use; if the content of the tin paste is large, it needs to be mixed with a special thinner.

Solder paste in the storage and use of the process will always produce chemical reaction, although this reaction is inevitable, but the reasonably designed solder paste in the normal use of the conditions of the reaction rate should be quite slow, so that its service life is sufficient to cope with normal production needs. It can be transported in refrigerated trucks and stored in factory warehouses using freezers for refrigeration. Solder pastes that are prone to drying out are often the result of defects in the design of the formulation. Additionally, ensuring a compliant operating environment and standardized handling can extend the life of the paste. Other factors, such as solvent evaporation during use, may also have an effect on the service life, but are not a major factor.

In the use of solder paste in the process, to strictly comply with the specifications for the use of solder paste, otherwise it will affect the characteristics of the solder paste itself, resulting in poor soldering; that to use what brand of solder paste is better.

Recommended Noble Flower lead-free solder paste, a wide range of uses, environmental protection solder paste professional to rest assured that can meet the SMT production of temperature resistance has special welding requirements of the product. Consulting customer service staff, for you to recommend high quality, good price and cheap solder paste products, good quality and good service is our advantage!

苏公网安备32058302004438

苏公网安备32058302004438