Views: 1 创始人: Site Editor Publish Time: 2024-11-12 Origin: Site

Process flow and precautions

BGA Solder

Ball Reset Process

I.

Introduction

With the continuous development of

electronic devices towards miniaturization and high performance, ball grid

array (BGA) packaging technology has been widely used in the field of

integrated circuits. BGA

packages are favored for their high pin count, good electrical performance, and

compact package structure. However, during the production, assembly, and use of

BGA packages, problems such as damaged BGA solder balls or poor soldering may

occur, and the BGA solder ball reset process is required to repair them to

ensure the normal operation of electronic equipment. BGA

as a large-capacity package SMD to promote the development of SMT,

manufacturers and manufacturers have recognized: in the large-capacity pin

package BGA has a strong vitality and competitiveness, but BGA single device is

expensive, for pre-research products often have multiple tests, often need to

remove BGA from the substrate and want to reuse the device. Because the solder

ball is destroyed after the BGA is removed, it can not be directly soldered on

the substrate, and the ball must be re-positioned, and the technical problem of

how to regenerate the solder ball is in front of our process technicians. BGA

balls can be purchased at Nofil Electronics, but the process of repairing each

BGA ball one by one is obviously not advisable, and this article introduces a

SolderQuick process technology for solder ball regeneration of BGA in preform.

2. The

structure and function of BGA solder balls

The

bottom of the BGA package is covered with dense solder balls, which are usually

made of tin-lead alloy or lead-free alloy. Solder balls serve as electrical

connections, mechanical support, and heat conduction. From the perspective of

electrical connection, it accurately connects the pins of the BGA chip with the

pads on the printed circuit board (PCB) to realize the

transmission of signals; In terms of mechanical support, the solder ball

supports the position of the BGA chip on the PCB to prevent the chip from

displacing when it is subjected to external forces; In terms of heat

conduction, the solder ball can effectively conduct the heat generated when the

chip is working to the PCB board, and then dissipate it through the heat

dissipation path on the PCB.

3. The

reason for the damage of the BGA solder ball or poor welding

Problems in the production process

In the manufacturing process of BGA

packaging, if the soldering process parameters are not properly controlled,

such as the temperature profile of reflow soldering is not set properly, it may

lead to poor solder ball molding. Too high a temperature may oxidize the solder

balls, while too low a temperature may result in insufficient soldering of the

solder balls to the die pins or PCB pads.

The quality of the material cannot be

ignored. If the purity of the solder ball itself does not meet the

requirements, or if it is contaminated during storage, it may affect its

welding performance.

factors in the assembly process

When assembling BGA chips onto a PCB board,

inaccurate alignment is a common problem. If the BGA chip is not precisely

aligned with the pads on the PCB, some of the solder balls will not be soldered

properly.

External forces during the assembly process

can also deform or displace the solder balls. For example, during the operation

of the placement machine, if the movement speed of the device is too fast or

the acceleration is too large, it may have a large impact on the BGA chip,

which will affect the state of the solder ball.

Use environment and aging

Changes in ambient temperature and humidity

may have an impact on BGA solder balls during the use of electronic devices. A

high humidity environment can cause corrosion of the solder ball, and repeated

changes in temperature may cause stress due to thermal expansion and

contraction, causing the connection between the solder ball and the pin or pad

to loosen.

Long-term use can cause aging of electronic

devices, and BGA

solder balls are no exception. After several thermal cycles, the internal

structure of the solder ball may change, which will affect its welding

performance.

Fourth,

BGA solder ball reset process steps

Ⅰ.Preparation: Confirm that the BGA's

fixture is clean, and then heat the flow oven to the temperature profile

required process steps and precautions. Clean BGA chips and PCB pads

For the removed BGA chip, use a special cleaning solvent and tool to clean the residual solder on the bottom of it. Excess solder can be removed using a solder suction wire or solder suction pump to ensure that each solder ball position is flat and smooth.

The pads on the PCB board also need to be

cleaned. Wipe the pads with a solvent such as alcohol to remove oil, oxide

layers, and residual solder. Then, use a microscope to inspect the pads for

damage, such as short circuits, open circuits, or detached pads. If there is a

damaged pad that needs to be repaired, you can repair the wire or remake the

pad.

<!--[if !supportLists]-->1.<!--[endif]-->Put the

preforming bad into the fixture, put the preforming bad into the fixture, mark

the side of SolderQuik face down, and ensure that the preforming bad and the

fixture are loose if the preforming bad needs to be bent to load the fixture,

then you can't enter the operation of the later process The preforming bad can

not be put in, the fixture is mainly caused by dirty things on the fixture or

improper adjustment to the flexible fixture.

<!--[if !supportLists]-->2.<!--[endif]-->Apply an

appropriate amount of flux to the reworked BGA, and apply a small amount of

flux to the solder surface of the BGA to be reworked with a syringe filled with

flux, noting that the BGA solder surface is clean before applying the flux.

<!--[if !supportLists]-->3.<!--[endif]-->Apply the

flux evenly, and use an acid-resistant brush to evenly brush the flux on the

entire soldering surface of the BGA package Ensure that each pad is covered

with a thin layer of flux, and the flux ensures that each pad has flux, and the

welding effect of thin flux is better than that of thick.

<!--[if !supportLists]-->4.<!--[endif]-->Put the BGA

to be reworked into the fixture and the BGA to be reworked into the fixture The

flux-coated side is against the preform break.

<!--[if !supportLists]-->5.<!--[endif]-->Lay the bag

flat and gently press the BGA so that the preform and BGA enter the fixture to

position, and confirm that the BGA is flat on the preform bad.

<!--[if !supportLists]-->6.<!--[endif]-->For reflow

soldering, the fixture is placed in a hot air convection oven or hot air reflow

station and the reflow heating process begins, all reflow station curves used

must be set to the curves specific to the developed BGA ball regeneration

process.

<!--[if !supportLists]-->7.<!--[endif]-->To cool,

remove the clamp from the furnace or reflow station with tweezers and place on

a thermal pad to cool for 2 minutes.

<!--[if !supportLists]-->8.<!--[endif]-->Remove, and

when the BGA has cooled, remove it from the fixture and place it with its

solder ball side up in the cleaning tray.

<!--[if !supportLists]-->9.<!--[endif]-->Soak the BGA

in deionized water for 30 seconds until the paper carrier is soaked before

proceeding to the next step.

<!--[if !supportLists]-->10.<!--[endif]-->Peel off

the solder ball carrier and remove the solder ball from the BGA with special

tweezers, preferably from one corner

<!--[if !supportLists]-->11.<!--[endif]-->。 The

peeled paper should be intact If the paper is torn during the peeling process,

stop immediately Add some deionized water and wait 15 to 30 seconds before

continuing.

<!--[if !supportLists]-->12.<!--[endif]-->Remove the

paper scraps from the BGA, after peeling off the carrier Occasionally a small

amount of paper scraps will be left Clip the paper scraps away with tweezers

When using tweezers to clip the paper scraps, the tweezers are welding. Be

careful to move the tweezers gently between the tweezers and the tip is sharp,

as you can scratch the fragile solder mask if you're not careful.

<!--[if !supportLists]-->13.<!--[endif]-->Cleaning,

immediately after removing the paper carrier, put the BGA in deionized water to

clean, rinse with a large amount of deionized water and brush the BGA with

power, carefully support the BGA when brushing with a brush to avoid mechanical

stress. Note that for best results, brush in one direction, then turn 90

degrees, brush in one direction, and turn another 90 degrees. Brush in the same

direction until 360 degrees.

<!--[if !supportLists]-->14.<!--[endif]-->Rinse,

rinse the BGA in deionized water This will remove the small amount of flux that

remains and the paper scraps that remain in the previous cleaning step and then

air dry, not dry it with a dry paper towel.

<!--[if !supportLists]-->15.<!--[endif]-->Inspect the

package, use a microscope to inspect the package for contamination, missing

solder balls, and flux residues, and repeat if cleaning is required.

<!--[if !supportLists]-->16.<!--[endif]-->Note that

since the flux used in this process is not a no-clean flux, careful cleaning to

prevent corrosion and prevent long-term reliability failure is required, and

the best way to determine if the package is clean is to test for ionic

contamination with an ionization diagram or an effective device All process

test results must meet the standard of contamination below 0.75mg NaaCI/cm, and

3.2.9-3.2.13 cleaning steps can be replaced by a sink cleaning or spray

cleaning process.

First of all, you need to use a

professional heat gun or rework station to heat the BGA chip. In the heating

process, the temperature, wind speed and heating time of the heat gun should be

reasonably set according to the size of the BGA chip, packaging material and

other factors. In general, the temperature is usually set between 200 - 300°C and the wind speed is moderate to avoid thermal damage to the

surrounding elements. When the solder ball is melted, use tweezers to gently

remove the BGA chip from the PCB board.

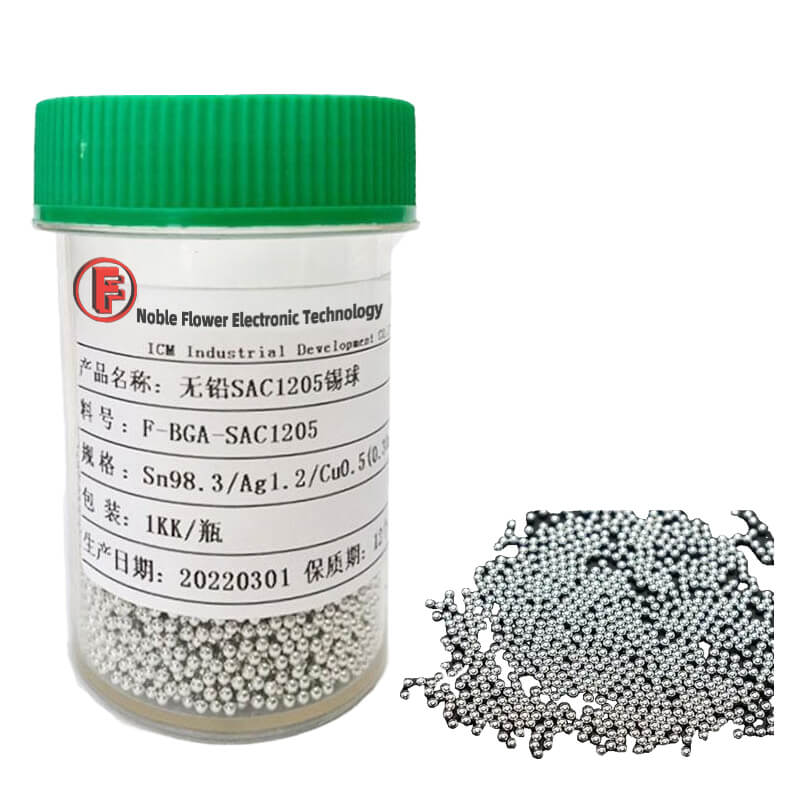

II. Ball planting

Ball planting is a critical step in the BGA

ball reset process. The first step is to choose the right size and composition

of the solder ball. Apply the flux evenly to the solder ball position of the

BGA chip, and then use the ball planting template to place the solder ball

exactly in the corresponding position. The hole diameter of the ball planting

template should match the diameter of the solder ball to ensure that the solder

ball can be placed accurately. Once the solder ball is placed, it needs to be heated

and cured to make the solder ball firmly connected to the chip pins. Generally,

reflow soldering is used for heating, and the temperature curve is set

according to the material and size of the solder balls.

Re-soldering

III.. Reposition the BGA chip on the PCB to

ensure that the chip is accurately aligned with the pad. Welding is then

carried out using a heat gun or a rework station. During the soldering process,

the temperature and time should be strictly controlled to ensure good soldering

between the solder ball and the PCB pad. After the welding is completed, the

welding quality is checked by X-Ray inspection equipment to see if there are

problems such as virtual welding and short circuit. If a problem is found, it

needs to be reworked in a timely manner.

5. Quality

control in the BGA solder ball reset process

Personnel training

Personnel engaged in the BGA solder ball

reset process must be professionally trained and familiar with the structure

and principle of the BGA package and the various steps of the reset process.

Only with sufficient professional knowledge and operational skills can the

quality of the process be guaranteed.

Calibration of equipment and tools

Heat guns, rework workstations,

microscopes, X-Ray

inspection equipment, etc., must be calibrated before use. For example, the

temperature and velocity of the heat gun need to be accurately measured to

ensure that the right amount of heat and airflow is provided during the heating

process. The magnification and clarity of the microscope need to meet the

requirements for inspecting pads and solder balls, and the X-Ray inspection

equipment needs to be able to accurately detect defects inside the weld.

Inspection of materials

For materials such as solder balls, fluxes,

and cleaning solvents, they should be strictly inspected before use. Check

whether the size, composition, and surface quality of the solder ball meet the

requirements, whether the activity and residue of the flux meet the standards,

and whether the purity of the cleaning solvent is sufficient.

VI.

Conclusions

The

BGA solder ball reset process is an important means to solve the solder ball

problem in BGA packaging. Through the in-depth understanding of the BGA solder

ball reset process, including its cause analysis, process steps, and quality

control, the repair success rate of BGA packages can be improved, thereby

extending the service life of electronic devices and reducing production costs.

In the field of electronic manufacturing and maintenance, it is very important

to continuously optimize the BGA solder ball reset process and improve the

reliability and stability of the process. In the

development of the BGA ball reset process, it is important to refer to the

various process steps and precautions mentioned earlier. From the perspective

of the process flow, each step is closely linked, and the negligence of any

link may lead to unsatisfactory final results.

In the preparation phase, for example,

cleaning is the foundation. As mentioned in the text, specialized tools and

solvents must be used for the cleaning of BGA chips and PCB pads. If the

residual solder, oil or oxide layer is not thoroughly cleaned in this link, the

subsequent welding work may appear false soldering or poor soldering. In

practice, we have encountered such a case, due to the lack of careful

inspection of the cleanliness of the PCB pads, resulting in some solder balls

failing to effectively connect with the pads in the subsequent reflow soldering

process, and eventually the function of the entire BGA chip was affected.

Choosing the right ball size and

composition is key when it comes to ball planting. This depends not only on the

specifications of the BGA chip itself, but also on the subsequent use

environment and performance requirements. At the same time, the uniformity of

flux application and the matching of the pore size of the ball planting

template directly affect the accuracy and firmness of ball planting. In an

actual production test, due to uneven flux application, some of the solder

balls failed to connect securely to the die pins after heat curing, resulting

in unstable signal transmission after re-soldering to the PCB.

In the re-soldering stage, the centering

operation and the control of temperature and time are the most important.

Precise alignment ensures that each ball can be connected to the corresponding

PCB pad, while tight temperature and time control avoids problems such as

oxidation of the solder balls due to overheating or insufficient soldering.

When we were repairing a batch of electronic equipment, we found that due to

the high temperature during soldering, some of the solder balls were oxidized,

which in turn affected the electrical performance of the entire BGA package.

In terms of quality control, personnel

training, calibration of equipment and tools, and inspection of materials are

the three pillars to ensure the quality of the BGA solder ball reset process.

Only if the operator has sufficient expertise and is able to master the

individual process steps can he be sure that every operation meets the

standard. The calibration of equipment and tools provides accurate and reliable

operating conditions, while the inspection of materials guarantees the quality

of the process at the source. For example, if a non-dimensional solder ball is

used, it is difficult to guarantee the success of the BGA ball reset process,

no matter how precise the subsequent operation is.

To sum up, every detail of the BGA solderball reset process needs to be paid close attention to, and by continuously

summarizing experience, optimizing the operation process and strengthening

quality control, we can better realize the repair of BGA packaging and improve

the overall performance and service life of electronic equipment.

苏公网安备32058302004438

苏公网安备32058302004438